We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best 12 Inch Miter Saw Blade

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best 12 Inch Miter Saw Blade

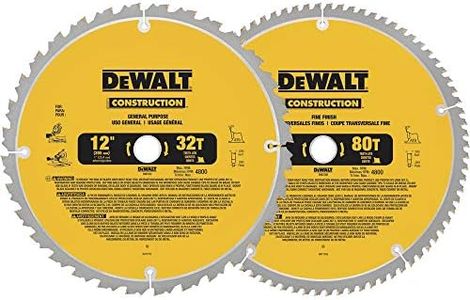

When choosing a 12-inch miter saw blade, it's important to think about the specific tasks you'll be using it for, such as cutting wood, laminate, or even metal. Every blade is designed with certain materials and purposes in mind, so understanding the main features can help you get cleaner cuts, make your saw safer to work with, and ensure longer blade life. Start by identifying the main materials you'll be working with and the types of cuts (fine, rough, angle, crosscut, rip, etc.) you want to make. The right blade will make your projects faster, easier, and more enjoyable.Tooth CountTooth count refers to the number of cutting teeth on the blade. More teeth mean a smoother, cleaner cut, while fewer teeth provide faster, rougher cuts. Low-tooth blades (around 24-32 teeth) are best for quick, rough cuts and are ideal for ripping through thick lumber. Medium-tooth blades (around 40-60 teeth) offer a balance between speed and smoothness, which works well for general purpose cutting and some finish work. High-tooth blades (80 teeth or more) are designed for fine, smooth cuts and are perfect for trim, molding, and finish carpentry. Match the tooth count to the finish quality you need and the type of materials you’ll cut most often.

Material and CoatingThe blade material, often carbide-tipped steel, affects its performance and lifespan. Carbide-tipped blades last longer and stay sharp, suitable for frequent and professional use. Some blades come with special coatings that reduce heat buildup and prevent gum or pitch from sticking to the blade, which can extend its life and keep cuts cleaner. If you’ll be cutting hard materials or using the saw often, choosing a carbide-tipped and coated blade can save you time on maintenance and replacements.

Kerf WidthKerf is the thickness of the cut the blade makes. Thin kerf blades remove less material, making them easier for lower-powered saws to use and reducing waste. Standard kerf blades are thicker, offering more stability for heavier-duty saws and jobs. Choose thin kerf if you’re using a less powerful saw or want to save material; go for a standard kerf if you need strength and durability, such as for frequent or tough cutting tasks.

Tooth GeometryTooth geometry (the shape and angle of each tooth) affects the type of cuts a blade can make. Alternate Top Bevel (ATB) blades are common for crosscutting wood and making smooth finish cuts. Flat Top Grind (FTG) is tougher and suited for ripping lumber. Combination and triple-chip grind teeth handle a mix of materials or specialty jobs. Think about your main cutting needs—if you’re mostly doing crosscuts for trim, go for ATB; if you do a mix, consider a combination blade.

Arbor SizeArbor size is the hole in the center of the blade that mounts onto the saw’s spindle. Most 12-inch miter saws use a specific arbor size, and it’s important your blade matches this exactly for safe, steady operation. Always check your saw’s manual for the required arbor size and be sure the blade you pick fits perfectly.

Intended Material UseBlades are often designed with a specific material in mind: wood, laminate, plywood, non-ferrous metals, or plastics. Using the right blade for the right material makes a huge difference in cut quality and blade life. If you mostly cut wood, stick with a wood-specific blade; for occasional cuts in metal or laminate, look for a blade rated for multiple materials.