We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Abrasive Cut Off Wheels

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Abrasive Cut Off Wheels

Choosing the right abrasive cut-off wheel is essential for effective and safe cutting of various materials, from metals to ceramics. The perfect wheel depends on what you are cutting, your tool’s compatibility, and your desired finish. Before purchasing, always consider the material, thickness, and intended application, as these factors influence performance and safety. Understanding each key specification will help you match the wheel to your needs so you get efficient cuts with minimal waste or risk.Wheel MaterialThe wheel material refers to what abrasive compound the cut-off wheel is made from, such as aluminum oxide, silicon carbide, or diamond. This spec matters because certain materials are better suited for specific tasks; for example, aluminum oxide works well with steel, while silicon carbide is preferable for stone or non-ferrous metals, and diamond wheels are ideal for hard materials like ceramics. When looking at options, divide wheels into those made for metals, those for masonry, and those for specialty tough materials. Think about what you will most frequently cut; choose a wheel material specifically designed to handle that substance efficiently.

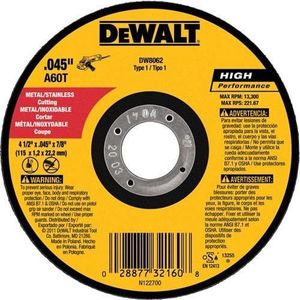

Wheel DiameterWheel diameter is the measurement across the wheel and is key for determining the size of cuts you can make and the types of tools that are compatible. Larger diameters allow deeper cuts and are typically used with stationary cut-off machines, while smaller diameters fit hand-held tools for finer or more detailed work. Typically, wheels come in small (under 4 inches), medium (4-7 inches), and large (over 7 inches) sizes. Your choice should match your tool’s specifications and the thickness of the materials you plan to cut most often.

ThicknessThe thickness of a cut-off wheel affects the width of the cut and the level of precision. Thinner wheels create narrower cuts and are better for quick and precise work, while thicker wheels are sturdier and suitable for heavier-duty applications or materials that need more stability during cutting. Thickness values usually range from ultra-thin (less than 1mm), standard (1-3mm), to heavy-duty (over 3mm); consider thinner wheels for delicate or detailed cuts and thicker wheels for rough or bulky materials.

Bond TypeBond type is about how the abrasive particles are held together in the wheel, commonly resin or vitrified bonds. This matters because it influences how fast the wheel wears down and its resistance to heat and pressure. Resin-bonded wheels are flexible and absorb shock well, making them popular for cut-off operations, while vitrified bonds are harder and resist heat but can be brittle. When choosing, match the bond type to your cutting style: if you need durability for steady, long cuts, go vitrified; for smoother, faster cuts, opt for resin.

Maximum RPM (Revolutions Per Minute)The maximum RPM is the highest speed at which the wheel can safely spin. This is crucial for safety, as exceeding this limit can cause the wheel to shatter. You will find wheels categorized for low, medium, and high RPM values—always compare this number with the speed rating of your tool. Always choose a wheel whose maximum RPM is equal to or greater than your tool's top speed to ensure safe usage.

Application TypeApplication type refers to the intended use of the wheel, like metal cutting, masonry, or multi-material. Some wheels are designed purely for speed, others for smoothness or longevity. These are often labeled by manufacturers, but you should also think about whether you value speed, a fine finish, or longevity. Picking the right application type ensures faster, cleaner, and safer results tailored to your regular projects.