We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

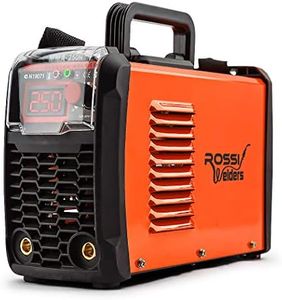

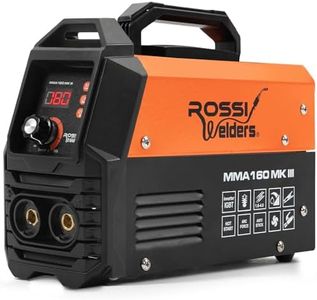

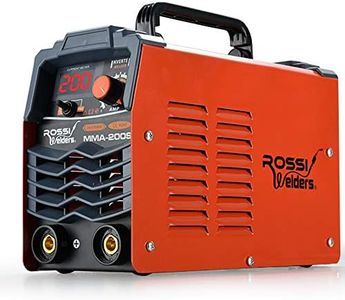

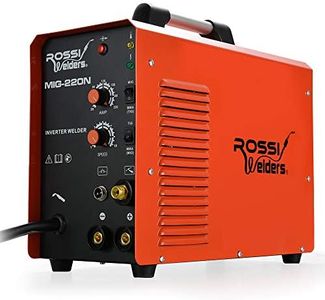

10 Best Affordable Stick Welder

From leading brands and best sellers available on the web.Buying Guide for the Best Affordable Stick Welder

Choosing an affordable stick welder is about matching your expected projects with the right features, power, and usability. Stick welders, also known as arc welders, are great for beginners and experienced welders alike thanks to their simplicity, ability to work outdoors, and versatility with various metals. When shopping for one, it's important to consider what you'll be welding, how often, and in what environments, as this will help you find a model that is both capable and easy to use.Amperage RangeAmperage, measured in amps, determines the thickness of metal you can weld and how much heat is produced. Lower amperage (up to 100A) is suitable for thin metals and light repairs. Mid-range (100A-160A) covers most home and farm projects, letting you weld everyday items like gates or frames. The highest range (above 160A) is helpful for heavy, thick materials often encountered in industrial work. Choose the amperage range that matches the thickness of the materials you'll most often weld.

Input VoltageThe input voltage tells you what kind of electrical supply is required. Most affordable stick welders work on household outlets (120V), making them convenient for home use. Some handle dual voltage (120V/240V), providing flexibility if you anticipate tougher jobs or have access to higher voltage circuits. Your choice should reflect where you'll be working—standard home outlets or a shop with heavier power.

Duty CycleDuty cycle indicates how long the welder can operate safely within a ten-minute span before needing a break to cool down. A higher duty cycle (like 40%-60% at certain amperages) means more continuous work without interruption—a bonus for longer welds or bigger projects. Lower duty cycles (around 20%-30%) are fine for short, quick jobs. If you plan on welding for extended periods, look for a higher duty cycle.

Weight and PortabilityWeight affects how easily you can move the welder around your workspace or job site. Lighter models are very portable and perfect if you’ll frequently move the machine or work in different locations. Heavier ones can offer more power but may not be as convenient to transport. Think about whether portability or stationary use is more important for your typical projects.

Electrode Size CompatibilityStick welders use consumable rods, called electrodes, which come in different sizes. The welder should support the electrode sizes needed for your jobs: smaller rods (1/16" or 5/64") for thin materials, standard rods (1/8") for everyday repairs, and larger rods (up to 5/32") for thick or structural metal. Make sure the welder matches the electrodes most suitable for your anticipated projects.

Ease of Use and Safety FeaturesUser-friendly controls, clear displays, automatic arc start, and features like thermal overload protection or anti-stick help beginners produce better welds and stay safe. If you're new to welding, look for models with simple settings and built-in safety functions, so you can focus on learning and practicing without unnecessary complications.