We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Air Filtration For Wood Shop

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Air Filtration For Wood Shop

Choosing the right air filtration system for your wood shop is essential for both your health and maintaining a clean workspace. Fine dust generated from woodworking can remain suspended in the air and negatively affect breathing, tool performance, and the finish of your projects. To find the ideal filter, you should consider factors that impact how well the unit removes dust, how easy it is to use, and how it fits into your workspace. By paying attention to the following key specs, you'll be equipped to make a smart decision tailored to your shop's needs.Airflow Capacity (CFM)Airflow capacity, measured in cubic feet per minute (CFM), tells you how much air the filtration unit can move each minute. This is important because higher airflow means more air is filtered in less time, which is crucial in a shop where a lot of dust is created. Typically, smaller shops can use units around 300–600 CFM, average workshops might need 600–1000 CFM, and larger or busier spaces may require 1000 CFM or more. To choose what's right for you, consider the volume of your space (length x width x height) and look for a system that can cycle all the air several times per hour; this ensures dust is efficiently removed from your work environment.

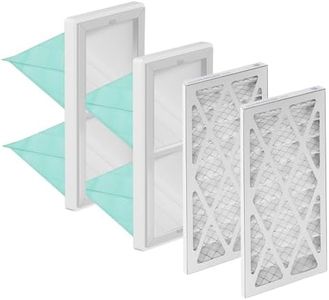

Filtration StagesFiltration stages refer to how many separate filters the air passes through before it's considered 'clean.' Many systems use at least two: a pre-filter for capturing larger pieces like chips or shavings, and a finer filter for small dust particles. Some advanced systems may include a third filter, like a HEPA stage, to trap ultrafine particles. More stages generally mean more effective cleaning, but they can also result in more maintenance. If you frequently generate both fine and coarse dust, a multi-stage system helps keep your air safer and your equipment running smoothly.

Particle Filtering EfficiencyThis spec tells you how small of a particle the filter can trap, often measured in microns. For wood dust, filters should ideally capture particles as small as 1 micron or less, since the tiniest dust is also the most hazardous to breathe. Filters in the 5–10 micron range are basic and only catch larger dust, while 1–5 micron filters offer much better protection. HEPA-level filters go down to 0.3 microns and provide the highest level of safety, though they may cost more to maintain. If you do fine sanding or want the cleanest air possible, prioritize filters that catch smaller particles.

Noise LevelThe noise level, usually rated in decibels (dB), impacts your comfort while the system is running. Lower numbers are quieter, while higher numbers can become distracting or even damaging with prolonged exposure. Small, portable units often run at about 50–60 dB (like a conversation), and larger units can be over 70 dB (like a vacuum cleaner). Consider how much time you spend in the shop and what level of noise you find tolerable; if frequent, quieter units reduce fatigue but may have lower airflow. Choose based on your desired balance between power and comfort.

Mounting Options and SizeAir filtration systems can be portable, wall-mounted, or ceiling-mounted. The right type depends on your shop's size and layout. Portable units are ideal for small shops or for moving to specific areas, but ceiling-mounted units save floor space and excel in larger or more permanent setups. Make sure to measure your available space and consider how you'll access the unit for filter changes. Choose a mounting style that fits comfortably in your shop and won't interfere with your workflow.

Ease of Filter ReplacementFilter replacement is a routine maintenance task, and some designs make it easier than others. Look for systems with simple access panels or tool-free removal to minimize downtime. If you do a lot of sanding or cutting, you'll likely change filters more often, so convenient replacement will save you time and hassle. Always check how often filters are recommended to be changed for your level of use and choose a unit you'll be comfortable maintaining.