We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best American Made Bench Vise

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best American Made Bench Vise

Choosing a bench vise made in the USA means you're likely interested in quality, durability, and supporting local manufacturing. Picking the right bench vise starts with understanding your own workshop needs—are you doing heavy-duty tasks, occasional DIY, or precise hobby work? Think about the type of projects you'll tackle most often. Pay attention to build materials and construction, which can influence how long the vise lasts and how well it performs. Finally, ease-of-use features and mounting options can make a big difference in your day-to-day satisfaction.Jaw WidthJaw width refers to the horizontal length of the vise's clamping surface. It's important because it determines how large an object you can grip securely. Jaw widths typically fall into segments like compact (3-4 inches), standard (5-6 inches), and heavy-duty (7 inches or more). For most home or light workshop tasks, a standard jaw width is versatile. If you’re frequently working with large or irregular pieces, opt for a wider jaw; for fine or delicate jobs, a narrower jaw offers more control.

Jaw OpeningThis specification indicates the maximum distance the jaws can open apart. It determines how thick or large a piece you can clamp inside the vise. Jaw openings are usually categorized as small (3 inches or less), medium (4-6 inches), and large (7 inches or more). If you work on a variety of projects with different materials, a medium to large jaw opening gives you flexibility. For smaller, repetitive tasks, a smaller jaw opening may suffice and save workbench space.

Clamping ForceClamping force is the amount of pressure the vise can apply to hold your workpiece. It’s vital because the right amount of pressure ensures your work stays put without slipping or damaging what you’re working on. Light-duty vises exert less force and are suitable for hobby tasks, while heavy-duty vises offer greater clamping force for tough materials or demanding jobs. Consider the typical materials you handle; metals and thick wood call for more clamping force, while softer materials need gentler pressure.

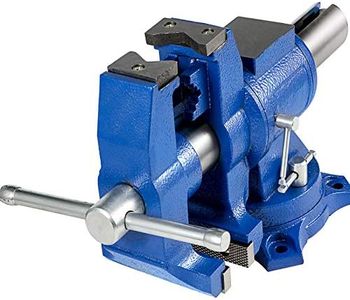

Material and Build QualityThis refers to what the vise is made of, such as cast iron, steel, or ductile iron, and how well it’s assembled. A bench vise’s material affects its strength, durability, and resistance to wear or cracking. Cast iron is common and durable for most tasks; ductile iron or forged steel offers even greater toughness for heavy-duty use. Assess your needs: general workshops are well-served by quality cast iron vises, while professional or industrial users might need advanced materials for years of heavy use.

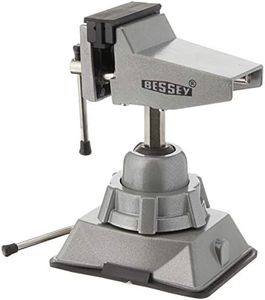

Swivel BaseA swivel base allows the vise to rotate horizontally, making it easier to adjust your workpiece position without taking it out of the vise. Some vises are fixed and don’t swivel, while others offer 120-degree, 180-degree, or full 360-degree rotation. If your work involves accessing different angles, a swivel base adds significant convenience; however, if you primarily work in a fixed direction, a stationary base can be more stable.

Mounting OptionsMounting options dictate how the vise attaches to your workbench—typically with bolts through pre-drilled holes or clamps for temporary setups. Secure mounting is essential for safety and stability. If you have a permanent workspace, bolt-down mounting provides the best security. For portable or temporary applications, a clamp mount might suit you better. Consider how and where you'll use your vise to determine the right mounting style.