We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

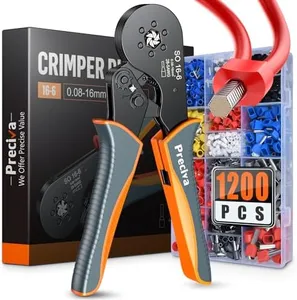

10 Best Automotive Wire Crimpers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Automotive Wire Crimpers

Choosing the right automotive wire crimper can make a big difference in the quality and reliability of your electrical work on vehicles. Crimpers are specialized tools used to attach wires to connectors without the need for soldering, ensuring secure electrical connections. When selecting a crimper, it’s important to think about the type and size of wires you'll be working with, the kinds of connectors you plan to use, and how often you expect to use the tool. Understanding the main features will help you find a crimper that matches your needs and gives you strong, consistent crimps every time.Crimping Range (Wire Gauge Compatibility)The crimping range refers to the sizes of wire (measured in American Wire Gauge, AWG) that the tool can handle. This is important because using a crimper outside its intended range can result in weak or unreliable connections. Wire gauges are identified by numbers, with lower numbers indicating thicker wires. Common automotive work usually involves wires between 10 and 22 AWG. Basic crimpers handle a small range, like 18-22 AWG, making them suitable for light-duty tasks, while broader-range crimpers can handle everything from 8-22 AWG, giving you more flexibility. Pick a crimper that matches the most common wire sizes you expect to work with—if you often handle a variety, a broader range is best.

Crimping Jaw or Die TypeThe crimping jaw or die is the part of the tool that shapes and presses the connector onto the wire. This is essential because different types of connectors and wires require different crimp patterns for the strongest hold. There are jaws for insulated and non-insulated terminals, open-barrel crimping, and more. Some crimpers have interchangeable dies for versatility, while others are fixed. If you regularly use different connector types, go for a tool with changeable dies. If your needs are consistent, a dedicated jaw can offer easier use and better performance for that specific task.

Crimping Mechanism (Ratchet vs. Non-Ratchet)The crimping mechanism determines how the tool closes and the amount of pressure it applies. Ratchet mechanisms lock the jaws closed until a full crimp is achieved, ensuring the same pressure each time and lowering the chance of incomplete crimps. Non-ratchet tools require you to judge when the connection is secure. If you want consistent results and plan to crimp a lot, a ratcheting crimper is much easier and more reliable. For the occasional repair or if cost is a concern, non-ratchet crimpers work but need more attention while crimping.

Ergonomics and Handle DesignErgonomics refers to how comfortable and easy the tool is to hold and use. Automotive wire crimpers vary in handle length, grip padding, and overall tool weight. This is important if you’ll be crimping many wires or working in tight spaces. Longer handles give more leverage but can be hard to maneuver in small areas, while padded grips reduce hand fatigue for extended use. People with larger or smaller hands will want to try the feel of the grip if possible. Think about how often you'll use the tool and in what locations—choose comfortable, slip-resistant handles for frequent or tricky jobs.

Built-in Wire Stripper and CutterSome automotive crimpers include extra functions like wire stripping and cutting built into the tool. This makes the tool more versatile and convenient, letting you prepare and crimp wires without needing to switch tools. However, adding more features can sometimes make the tool bulkier or less comfortable for some users. If you value having an all-in-one solution for efficiency, look for these built-in features. If you already have good separate strippers and cutters, a dedicated crimper may feel lighter and more focused.