We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

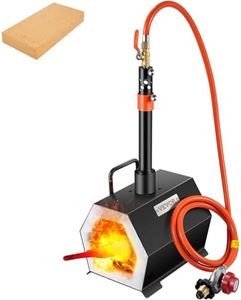

10 Best Blacksmith Forge

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Blacksmith Forge

Choosing a blacksmith forge is an exciting step for anyone interested in metalworking, whether you're just starting out or ready to upgrade your setup. The right forge can make all the difference in how efficiently and safely you work, and in the kinds of projects you can tackle. Before diving in, consider not only the physical space you have available but also the types of metals and projects you aim to work with. Getting familiar with the key specifications will allow you to make an informed choice that aligns with your needs and ensures both enjoyment and productivity in your workshop.Fuel TypeFuel type refers to what source of energy the forge uses to generate heat for metalworking. The common options are coal, propane, and sometimes charcoal. This is important because different fuels create different heat profiles, levels of mess, and operational requirements. Coal forges reach high temperatures and are favored for traditional work, but they require good ventilation and produce smoke and ash. Propane forges are cleaner, easier to start, and usually more beginner-friendly, but they rely on gas canisters and are often compact. Charcoal forges are less common and mostly used in historic or experimental settings. To choose the right one, think about your workspace (indoor or outdoor), how much maintenance you're willing to do, and your comfort with handling fuels.

Forge Size (Chamber Dimensions)Forge size indicates the physical dimensions of the heating chamber, which determines the size and number of metal pieces you can heat at once. This matters because too small a chamber limits your project size and throughput, while too large a chamber can waste fuel or take longer to heat up. Chambers vary from compact single-burner forges suitable for small knives or jewelry, to multi-burner or larger forges for bigger blades or tool making. To pick the right size, consider the typical shapes and lengths of metal you'll work with most often, and whether you'll ever want to heat multiple pieces at the same time.

Maximum Operating TemperatureThis specification tells you how hot the forge can get at peak performance. It's important because different metals require different temperatures to become workable, and certain metalworking techniques (like forge welding) demand the highest heat. For basic iron or mild steel work, most general forges will suffice; advanced smithing or working with specialty steels sometimes needs higher temperatures. Check the metals you plan to use and ensure the forge can comfortably achieve and maintain those heats, giving yourself a buffer so the forge isn't always running at its maximum.

PortabilityPortability refers to how easy it is to move and set up the forge. If your workspace is temporary, you work at fairs or events, or you need to store the forge between uses, portability becomes key. Light, compact forges are easy to move but may have smaller chambers or less power. Larger, heavier forges may work best for a permanent workshop. Think about where you'll use the forge most, and whether you'll need to move it around regularly, to guide your choice.

Ventilation RequirementsVentilation involves the air flow required to safely expel fumes, smoke, and heat generated during forging. This is important for health and safety, especially when using forges that produce smoke (like coal). Good ventilation prevents build-up of harmful gases and keeps your workspace comfortable. Propane forges generally produce fewer pollutants, but still need ventilation for heat and carbon monoxide. If you work indoors, ensure you can provide adequate exhaust and fresh air exchange; outdoor users have more flexibility but should still be cautious about wind direction and airflow.

Ease of Use and MaintenanceEase of use covers how straightforward it is to light, operate, and control the forge, while maintenance refers to how much ongoing work you'll need to keep it running safely. Simple systems are easier for beginners and those who may only forge occasionally. Some forges have automatic ignition and simple fuel controls, while others require skill to manage the fire or adjust airflow. Maintenance can include cleaning out ash, inspecting burner systems, or replacing fire bricks. If you're new to blacksmithing or want to minimize hands-on adjustments, look for straightforward operation and low-maintenance models.