We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Buffing Pads

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Buffing Pads

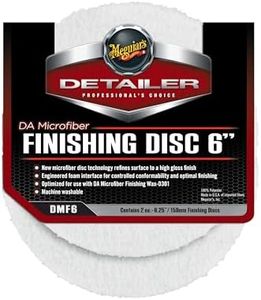

Buffing pads are essential tools for anyone looking to polish or restore the finish on a surface, such as automotive paint, furniture, or floors. Choosing the right buffing pad can make a significant difference in the quality of your results, as different pads are designed for different tasks and surface types. To pick the best buffing pad for your needs, it's important to understand the key specifications and how they influence performance, ease of use, and final finish.Pad MaterialPad material is crucial because it determines how the pad interacts with the surface and the type of finish you can achieve. Common materials include foam, wool, and microfiber. Foam pads are versatile and come in varying densities for cutting, polishing, and finishing. Wool pads are more aggressive, great for heavier paint correction or removing deeper scratches. Microfiber pads offer a balance and are effective for light corrections or finishing. For beginners or most general uses, foam pads are easiest to control and less likely to damage surfaces. Consider what surface you’re treating and the level of correction or shine you want—go for wool if you need heavy correction, foam for general use, or microfiber for finishing.

Pad SizePad size refers to the diameter of the pad and affects both the coverage area and how easy it is to control. Smaller pads (3-5 inches) are excellent for tight spots or detailed work, while larger pads (6-8 inches) cover more area and work faster on big surfaces. If you’re working on large, flat areas like car hoods, a larger pad can save time, but for contours, edges, or detail work, a smaller pad is safer and more precise. Choose the size based on your project’s surface area and the level of detail needed.

Pad Firmness/DensityPad firmness or density describes how hard or soft the pad feels. Harder (high-density) pads are more aggressive and used for removing deeper imperfections, while softer (low-density) pads are gentle and ideal for finishing or applying waxes and sealants. When picking firmness, think about the stage of your work—start with a firmer pad if you need to correct scratches, then switch to softer pads for polishing and final shining to avoid causing haze or swirls.

Pad Cut LevelThe cut level is about how much material the pad can remove from the surface. Heavy-cutting pads are for correcting significant defects; medium-cut pads handle light correction, and finishing pads are for light polishing or waxing. Consider your surface condition: if it has many scratches or oxidation, a higher cut level will speed up restoration, but always finish with a lower cut pad to bring out the shine and avoid dullness.

Backing TypeBacking refers to how the pad attaches to your machine, most commonly via hook-and-loop (Velcro) or adhesive. Hook-and-loop is easy to use, lets you swap pads quickly, and is reusable. Make sure the backing size matches your machine's backing plate for safety and even pressure. For most users and typical polishers, hook-and-loop backing is convenient and versatile.

Washability and DurabilityWashability is about how easily the pad can be cleaned after use, which impacts how long it lasts and its performance during multiple sessions. Pads designed for machine washing or easy rinsing are best if you plan on repeated use. Durability matters especially when working with tougher compounds or aggressive machines. Check for pads that are labeled as durable and washable to save effort and money over time.