We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Chainsaw Mill

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Chainsaw Mill

Choosing the right chainsaw mill can make a huge difference in how efficiently and safely you can turn logs into usable lumber. Understanding your needs, such as the type and size of wood you’ll be milling and how often you expect to use the mill, will help you focus on what matters most. Start by looking at where and how you plan to use it—whether it’s on site in the forest or at home with occasional logs. Matching the mill’s specs to your chainsaw’s capabilities is also critical to ensure smooth operation and to avoid damaging your equipment. By understanding the key specifications, you’re more likely to end up with a tool that makes milling easier, safer, and more productive for you.Cutting Capacity (Width Range)Cutting capacity refers to the maximum width of the log that the mill can handle. This is an important factor because it limits the size of the boards or slabs you can cut. Chainsaw mills commonly offer a width range, such as 12 inches to over 36 inches. For lighter, portable work or smaller logs, a narrower capacity (12-18 inches) is often sufficient and makes handling easier. For larger logs and bigger projects, look for mills that accommodate wider cuts (24 inches and up). Decide on the right width for you by considering the average size of the logs you’ll be milling; if you’re likely to encounter bigger logs, get a mill that provides a bit of extra capacity.

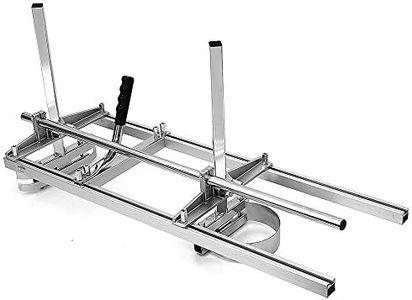

Build MaterialThe material of the mill frame, usually either aluminum or steel, affects durability, weight, and ease of use. Aluminum mills are much lighter, making them easier to move and set up, which is ideal for portability and occasional use. Steel models are heavier but offer extra strength and durability for frequent or heavy-duty milling. Think about how often you’ll need to move your mill and how rough your environments will be—light, portable aluminum works for easy transport, while heavy-duty steel is great for stationary or more demanding work.

Compatibility with Chainsaw SizeNot all mills work with every chainsaw; most mills have a recommended bar length range and sometimes a minimum engine power (measured in cc). Smaller mills can be used with 50-60cc saws and shorter bars, which are fine for light-duty or small-log work. For larger, hardwood logs, a bigger chainsaw (more than 70cc) with a longer bar is necessary, and you’ll need to make sure your mill can fit it. Be sure to match your current chainsaw (or the one you plan to buy) with the mill’s recommended specs to maximize safety and performance.

Height Adjustment MechanismHeight adjustment lets you set the thickness of the lumber you cut. A good adjustment system is important because it helps you achieve consistent, precise boards and slabs. Simpler mills may have basic clamp adjustments, while advanced models offer fine-tuned, quick-adjust mechanisms. For most occasional users, simple systems are sufficient, but if you want consistent results across many boards, or you plan to mill slabs for woodworking, look for mills with easy and precise adjustment controls.

Assembly and PortabilityHow easily you can assemble and transport the mill matters, especially if you plan to use it in different locations. Some mills are designed to come apart quickly without extra tools, while others are more permanent setups. Portable, easy-to-assemble mills make sense for people who’ll be moving between sites, while if you plan to leave your mill in one place, a heavier, more permanent assembly may be fine. Think about where and how often you’ll use the mill to decide which style fits your needs.