We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

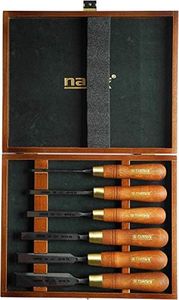

10 Best chisels

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best chisels

Choosing the right chisel is crucial for woodworking, carpentry, or even basic home repairs. A good chisel helps you shape, carve, and smooth wood efficiently and accurately. The right pick depends on your specific projects, skill level, and how you intend to use the tool. By understanding key specifications, you can select a chisel that fits comfortably in your hand and performs well for your intended tasks. Let’s look at the most important features to consider when picking a chisel.Blade MaterialThe blade material determines how sharp the chisel stays, how easy it is to sharpen, and how long it will last. Most chisels are made from types of steel, like carbon steel or chrome-vanadium steel. High-carbon steel holds a sharp edge longer and is easier to sharpen, making it good for detailed, precise work, while chrome-vanadium is more resistant to rust and may handle rougher treatment. For most users, if you're working with softwoods or occasional use, any quality steel will work, but for frequent or intricate woodworking, focusing on higher-carbon blades is worthwhile.

Blade WidthBlade width refers to how wide the cutting edge of the chisel is, typically measured in millimeters or inches. Wider blades (such as 1 inch or 25 mm) remove more material and are good for flattening and smoothing, while narrower blades (as small as 1/8 inch or 3 mm) are suited for fine detail, tight corners, or mortising. It's useful to match the width to your task: for carving or fine joinery, narrow blades are best, while for general purpose or removing lots of wood, wider blades are more efficient. Some users prefer a set with various widths for versatility.

Bevel AngleThe bevel angle is the slope on the chisel’s cutting edge. Standard bevel angles range from about 20 to 30 degrees. Lower angles (around 20 degrees) create sharper, finer edges for delicate slicing and paring, good for soft woods, but they dull faster with hard use. Higher angles (close to 30 degrees) are more durable and better for chopping or working with harder woods. Choose a lower angle if you plan on doing detailed or finishing work, and a higher angle if you expect more heavy-duty use.

Handle TypeHandle material and shape affect comfort and durability. Handles can be wooden or plastic, and the choice here affects grip and shock absorption. Wooden handles provide a traditional feel and may be more comfortable over long sessions, but are less durable when struck with a hammer. Plastic or composite handles are tough and better for heavy mallet work. Consider how much force you’ll need and how much time you'll spend using the chisel—long use suggests seeking comfort, while heavy work points to tougher handles.

Tang vs. Socket ConstructionThis refers to how the blade connects to the handle. Tang chisels have the blade’s metal ‘tang’ inserted into the handle, creating a lighter tool that’s good for fine control, but can break under strong impact. Socket chisels have a broader base that fits over the handle, making them tougher and more suited to heavy striking. For precise work or lighter use, tang construction works well, while for repeated hammering or heavy carpentry, socket designs are preferred.

Type of ChiselThere are many chisel types, including firmer, bevel-edge, mortise, and paring chisels. Firmer chisels are robust and all-purpose. Bevel-edge chisels have angled edges for getting into tight joints. Mortise chisels are thick and strong for cutting rectangular holes, while paring chisels are long and thin for delicate, accurate trimming. Think about the specific jobs you want to tackle. If you mainly do furniture repair, bevel-edge and paring chisels are good choices. For general heavy woodworking, firmer or mortise types work well.