We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

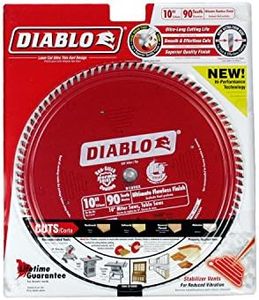

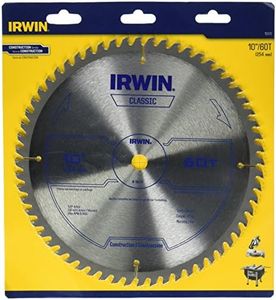

10 Best Circular Saw Blades

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Circular Saw Blades

Choosing the right circular saw blade is essential to get clean, accurate cuts and to make your sawing experience smoother and safer. Circular saw blades come in various types and sizes, each designed for particular materials and cutting tasks. To select the best one for your project, it's important to understand your material, the type of cut you want (rough or fine), and the specifications that matter most to your work such as size, teeth configuration, and material compatibility. Getting familiar with these main specs helps ensure you pick a blade that matches your needs and maximizes both performance and safety.Blade DiameterBlade diameter refers to the overall width of the blade from one edge to the opposite edge. This measurement is important because your circular saw is built to fit a specific blade size, and using the wrong diameter can be dangerous or simply not work. Common diameters include 6.5-inch, 7.25-inch, and 10-inch blades. Smaller blades are generally used for lighter, more portable saws and thinner materials, while larger blades are for heavier saws and can cut thicker or larger materials. Before choosing your blade, always check your saw's manual for compatible sizes and pick one that matches your cutting needs.

Tooth CountThe tooth count is the number of cutting tips on the edge of the blade. This is crucial because it affects the smoothness and speed of the cut. Blades with fewer teeth (such as 16 to 24) cut quickly and are best for rough jobs like cross-cutting framing lumber. Blades with more teeth (like 40, 60, or even 80) take smaller bites and are ideal for finishing cuts on plywood, laminates, or trim, leaving a cleaner edge. Consider what you’re cutting—use low tooth counts for fast, rough cuts and higher tooth counts for smoother, finer finishes.

Blade MaterialBlade material relates to what the blade is made of, which affects cutting performance and durability. Basic blades are often made of steel and are good for cutting soft woods. Carbide-tipped blades feature cutting edges made from a harder material, making them better for extended use and for cutting harder woods, laminates, or masonry. Specialty coatings can also help with heat resistance or pitch buildup. Depending on the intensity and frequency of your work, choose a material that balances durability and cost for the type of materials you'll cut most.

Kerf WidthKerf width is the thickness of the cut the blade makes as it moves through material. Thinner kerf blades remove less material and require less power, making them suitable for lightweight or battery-powered saws, and for fine, precise cuts. Standard or full kerf blades are sturdier and better for heavy-duty saws or thick stock but can create more drag and require more power. Think about your saw’s power and the precision you need: use thin kerf for tight fits and smoother cuts, and standard kerf when stability and strength matter more.

Tooth GeometryTooth geometry describes the shape and angle of the teeth on the blade, which greatly influences the type of cut and the materials you can work with. Common types include alternate top bevel (ATB) for cross-cutting and clean finishes, flat top grind (FTG) for fast, rough rip cuts, and triple-chip grind (TCG) for cutting laminated or hard materials. Decide on the tooth geometry based on the majority of your projects—choose ATB for general woodworking with a focus on clean crosscuts, FTG for speedy ripping, and TCG for specialty cutting needs.

Arbor SizeThe arbor size is the diameter of the hole in the center of the blade. This must fit the shaft on your saw. While arbor sizes are usually standardized per blade diameter, mismatches can prevent the blade from mounting securely or can be unsafe. Make sure to match your saw's arbor size exactly when selecting a blade, and always avoid using adapters unless recommended by the manufacturer.