We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

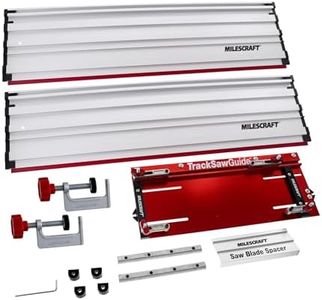

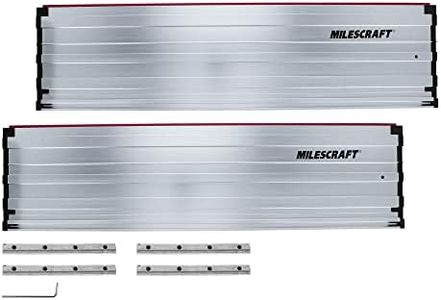

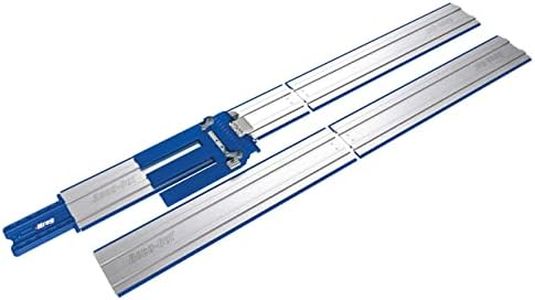

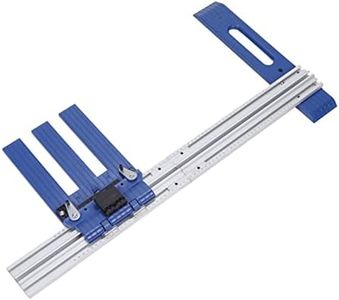

10 Best Circular Saw Track Guides

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Circular Saw Track Guides

Choosing the right circular saw track guide is essential to get accurate, straight, and clean cuts when using your circular saw. Track guides not only help in improving precision but also in maintaining safety and reducing material wastage. Since every project and user is a bit different, knowing what matters most to you—speed, portability, accuracy, ease of use—will really help you select the best fit. Begin by thinking about the types of cuts you make most often and the size of materials you work with, then use the key specifications as your guide.Track LengthTrack length refers to the overall length of the guide rail that the saw moves along. This spec matters because it determines the maximum length of cut you can make in a single pass. Tracks are usually found in sizes from about 24 inches up to several feet. If you usually work with small boards or do quick jobs, a shorter track might be lighter and easier to handle; for larger sheet goods like plywood, a longer track is more efficient and means fewer repositionings. Choose based on the size of materials you expect to cut most often.

Compatibility with SawsThis tells you which saws will actually fit or work properly with the track guide. Some tracks are universal and can adapt to a range of circular saws, while others are made only for specific brands or models. If you have a particular saw already, check that the track guide is either specifically compatible with it or can be adapted using accessories. Ensuring compatibility means you’ll have a stable setup and safe, clean cuts, without struggling with awkward fit or slipping.

Material and Build QualityMaterial and build quality indicate what the track is made from—common options are aluminum or steel—and how solidly the guide is constructed. Lightweight aluminum is easier to maneuver but might be less durable under heavy use; steel is sturdier but heavier to transport. A well-built track will stay straight and true, ensuring accuracy even after multiple uses, while a poorly constructed track could bend or warp. Pick a quality that matches your typical workload: for frequent, heavy-duty use, look for strong, rigid materials.

Anti-Slip FeaturesAnti-slip features are design elements like rubber strips on the bottom of the guide that prevent the track from moving while you cut. This is important for both precision and safety—if the guide slips, your cut could go off-line, potentially damaging material or causing an unsafe cut. Some tracks have better grip than others, so if you often cut heavier or more slippery materials, or work without clamps, you’ll want a guide with robust anti-slip protection.

Ease of Setup and UseEase of setup refers to how quickly and simply you can position and secure the track. Some guides offer tool-free adjustments or quick clamps, making it faster to align the track and get cutting. If you frequently move the guide or need to set up multiple cuts, a system that’s easy to put in place and adjust will save you time and frustration. Think about how much you value quick setup versus potential extra stability from more complex setups.