We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

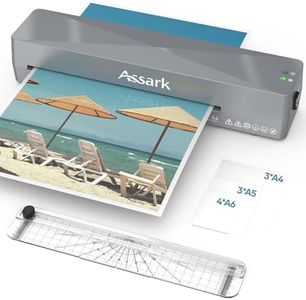

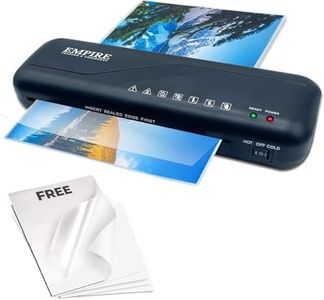

10 Best Cold Laminators

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Cold Laminators

Choosing a cold laminator can be quite straightforward once you know which features matter most for your intended use. Cold laminators are commonly used for protecting documents, photos, or signs without the use of heat, making them ideal for sensitive materials and environments where heated lamination could cause damage. It's important to consider the types of items you want to laminate, their sizes, and how often you'll use the machine. Taking the time to understand key specifications will help ensure that you choose a laminator that fits your daily tasks and lasts for years.Maximum Lamination WidthThe maximum lamination width is the widest material the laminator can handle in a single pass. This is crucial because it determines which sizes of paper, posters, or signs you can laminate. Smaller widths (such as up to 12 inches) are suited for standard documents and photos, while medium widths (15-25 inches) accommodate larger prints like menus or small posters. Wide-format laminators (above 25 inches) are best for banners and larger display items. To choose the right width, consider the types and sizes of items you most frequently laminate; if you need to work with a range of sizes, choosing a slightly larger width than your most common project offers more versatility.

Roller Type and QualityThe rollers in a cold laminator are responsible for evenly applying pressure to create a smooth, bubble-free finish. Higher quality or more rollers generally mean better results, especially for thicker or uneven materials. Some laminators have basic two-roller systems, which work for standard paper, while more advanced models may feature four or more rollers that handle thicker media and ensure a more professional finish. If you plan to laminate photos, artwork, or items with uneven surfaces, look for a model known for even pressure and more advanced rollers.

Thickness CapacityThickness capacity refers to the maximum thickness of materials (including the adhesive laminating film) that the machine can handle. Typical capacities range from 1mm to over 5mm. Lower capacity machines are best for standard paper and thin documents, while higher capacities allow for mounting thicker items like foam boards. Consider the thickness of both your document and lamination pouches or sheets, especially if you want to laminate signs or artistic projects that require added durability or rigidity.

Operation Mechanism (Manual vs. Electric)Cold laminators can be operated manually, usually via a hand crank, or electrically, by pressing a button. Manual machines are simple to use, portable, and less likely to break, but require more effort for each laminate. Electric laminators are faster and more suitable if you regularly laminate large batches, but they can be heavier and require power access. Your workflow can guide your choice; infrequent users or those needing portability can choose manual options, while frequent users benefit from the convenience of electric operation.

Ease of Film LoadingFilm loading refers to how easily you can insert or replace the laminating film or adhesive sheets in the machine. A user-friendly loading system saves time and reduces frustration, especially if you're laminating multiple batches or switching film sizes often. Some laminators offer easily accessible film rollers or intuitive threading guides, while others can be fiddly. If you're new to laminating or expect to swap films often, prioritize a machine that's reviewed as easy to reload.

Cutting FeaturesSome cold laminators include built-in cutting features, like rotary trimmers, which help you neatly trim the laminated product to size after passing through the machine. While not essential, a built-in cutter can save desk space and time. If you want seamless workflow and cleaner edges, or if you're producing laminated work for presentation, this feature can be especially handy. Otherwise, you may use a separate paper cutter.