We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

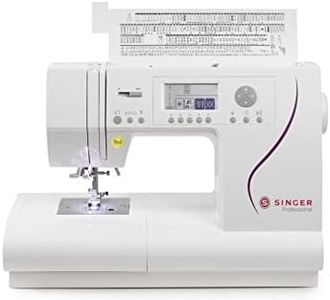

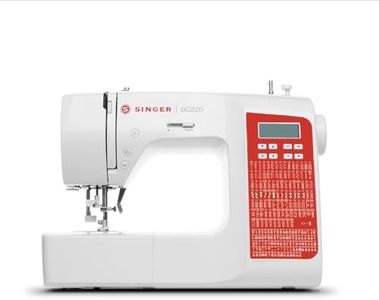

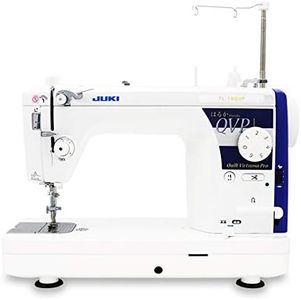

9 Best Commercial Grade Sewing Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Commercial Grade Sewing Machine

Selecting a commercial-grade sewing machine is all about matching the machine’s capabilities to the types of projects and the volume of work you expect to handle. Commercial sewing machines are designed for durability, speed, and consistent performance over long hours, unlike basic home machines. Before deciding, think about the materials you’ll work with (like light fabrics vs. heavy-duty canvas), the kinds of stitches you need, and how often the machine will be running. Understanding key specs will help you choose a sturdy machine that won’t slow you down or limit your creativity.Stitch Speed (Stitches Per Minute)Stitch speed tells you how many stitches the machine can make in one minute and is an indicator of how quickly you can finish projects. Faster speeds, like 1500 or more stitches per minute, are great for mass production and experienced users, while lower speeds are easier to control for delicate or precise work, especially if you’re still gaining experience with commercial machines. Think about the pace you feel comfortable working at and whether you need speed for higher output or prefer more control for detailed pieces.

Motor PowerMotor power, usually expressed in watts or as 'direct drive', reflects the strength of the machine and its ability to handle tough materials or many layers at once. Higher power means the machine can sew through thick fabrics like denim or leather without straining, making it crucial for upholstery or industrial tasks. If you plan to work mainly with lightweight fabrics, a moderate motor will suffice, but heavy-duty projects require a robust motor to maintain performance over time.

Stitch VarietyCommercial sewing machines range from very basic models offering just a straight stitch to advanced machines that include a range of decorative and functional stitches. If your work is specialized, like tailoring or quilting, make sure the machine has the stitches you need. For most garment or upholstery work, a straight stitch and a zigzag might be enough, but if you often take on creative or technical projects, a machine that offers more stitch options will provide greater flexibility.

Feed MechanismThe feed mechanism moves the fabric through the machine and affects how easy it is to sew different materials. Basic commercial models have a standard drop feed, while more advanced options offer walking foot, needle feed, or compound feed systems. These specialized mechanisms are important when working with thick, slippery, or multi-layered fabrics, ensuring even stitches and reducing shifting. Match the feed system to the types of fabrics you'll sew most frequently.

Construction and Frame MaterialThe build of the sewing machine, especially the frame, impacts its stability, longevity, and how well it handles heavy fabrics or high speeds. Commercial machines are typically built with metal frames and robust components, which reduce vibration and wear over time. If you need a machine to run several hours a day or regularly handle thick materials, a solid all-metal construction is essential, while lighter work may not require the heaviest frame.

Bed Type (Flat, Cylinder, Arm, Post)Bed type refers to the shape of the machine’s sewing surface. Flat bed machines resemble most regular sewing machines and are suitable for straightforward, flat work. Cylinder bed and post bed machines allow for sewing bulky, tubular, or awkwardly-shaped items such as cuffs, hats, shoes, or bags. The choice depends on your main business—if you mostly work on garments or simple projects, a flat bed is fine, but for specialty work like leather goods or upholstery, a cylinder or post bed may be more useful.