We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Corner Clamps

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Corner Clamps

Choosing the right corner-clamp can make woodworking, metalworking, or framing projects much easier and more precise. These tools are designed to hold two pieces at a right angle, helping you create perfect corners without struggling with shifting materials. Before making a decision, you should think about what type of projects you plan to use the clamp for and the kinds of materials you most often work with. A well-chosen corner clamp will improve your accuracy, save you time, and make your work more enjoyable.Jaw Opening (Capacity)Jaw opening, or capacity, refers to the maximum thickness of material the clamp can hold. It's important because it determines the size of the workpieces you can secure at a right angle. Small jaw openings (1-2 inches) suit light-duty jobs or narrow materials such as picture frames or small boxes. Medium openings (2-4 inches) are good for medium-sized woodworking, cabinetry, or light metalwork. Large openings (over 4 inches) are made for heavy-duty tasks or larger frames. Choose based on the most common material sizes you use; too small a clamp might not fit, while a larger one may be more versatile.

Material & Build QualityThe material a clamp is made from affects both its durability and weight. Most corner clamps are made from steel, aluminum, or heavy-duty plastics. Steel offers the highest strength and longevity but is heavier, suitable for large or demanding projects. Aluminum is lighter yet still sturdy, offering a good balance for general woodworking. Plastic clamps are fine for lightweight tasks or if you need to carry several clamps at once. Pick a build quality that matches the frequency and intensity of your work—frequent or heavy users should opt for metal, while occasional or hobby users may find plastic or aluminum sufficient.

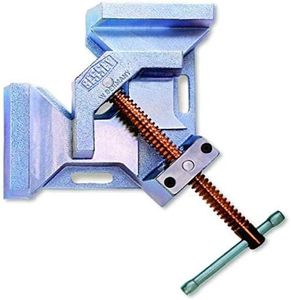

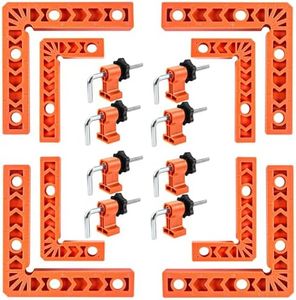

Clamping MechanismCorner clamps can use different clamping mechanisms—screw-type, quick-release, or ratcheting. Screw-type mechanisms offer precise adjustment and a strong hold, suitable for detailed work. Quick-release mechanisms let you rapidly clamp and release workpieces, ideal for repetitive tasks or assembly lines. Ratcheting clamps provide one-handed operation and adjust automatically to different thicknesses, great for convenience and speed. Choose a mechanism that fits your workflow; precision tasks benefit from screw-type, while volume tasks may call for quick-release or ratcheting.

Adjustability & VersatilitySome corner clamps are fixed at 90 degrees, while others are adjustable to accommodate a range of angles. Adjustable models are beneficial if your projects involve frames or joints that are not strictly square. Fixed models are usually sturdier for traditional right-angle corners. Consider whether you need to clamp only at 90 degrees or want the flexibility to handle other angles; pick based on the typical joints you make.

Ease of UseFeatures like ergonomic handles, quick-release buttons, and easy-to-turn screws make the clamp more comfortable to use and quicker to set up. This is especially noticeable when doing repetitive work or working with multiple clamps at once. If you value speed and convenience, look for features that simplify the clamping process.