We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Cutting Torches

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Cutting Torches

Choosing the right cutting torch is all about understanding your particular needs and how you’ll use the tool. Cutting torches are used for cutting through metals using a combination of fuel gas and oxygen, and picking the best one means paying attention to things like the materials you plan to cut, how thick those materials are, and how often you’ll use the torch. Knowing the main features can help you sort through options and find a torch that matches your work style and safety comfort as well.Type (Oxy-fuel vs. Plasma)The type of cutting torch you choose is important because it determines how the torch cuts through metal and what metals you can work on. Oxy-fuel torches use oxygen combined with a fuel gas (like acetylene or propane) and are best for cutting steel and iron, while plasma cutters use an electrical arc and compressed air, allowing you to cut a wider variety of metals, including stainless steel and aluminum. If you mainly need to work with iron or steel and want a traditional tool, oxy-fuel torches can be great. On the other hand, if you want faster cuts or need to work with more types of metal, plasma torches are worth considering.

Cutting Capacity (Thickness)Cutting capacity describes how thick of a material the torch can cut through, and it’s one of the most critical specs to check. This is usually given in inches or millimeters. Light-duty torches handle thin sheet metal, while heavy-duty torches can go through several inches of steel. If you only need to cut thin materials for DIY or automotive tasks, a lower capacity is fine and easier to use. For industrial work or if you anticipate cutting through thick metal, look for higher capacity, but keep in mind that higher capacity torches may be bulkier or require more gas.

Fuel Gas CompatibilityThe kind of fuel gas your torch accepts affects not only its cutting speed but also operation cost and convenience. Common gases include acetylene, propane, and sometimes natural gas. Acetylene is popular for its hot flame and fast cutting, but propane is sometimes chosen for its lower cost and better availability. When choosing a torch, check if it’s compatible with the gas you have access to or prefer to use, and be sure the fuel matches your safety preferences and the thickness and type of metal you’ll be working with.

Handle Comfort and WeightHandle comfort and the overall weight of the cutting torch affect how easy it is to control and how long you can use it without fatigue. Lightweight and ergonomic torches are easier for beginners and for jobs where precision and comfort matter, like detailed fabrication work or when using a torch for extended periods. For short, heavy-duty cuts, a heavier torch may be manageable, but if you know you’ll be holding the torch for a while, prioritize comfort and grip.

Safety FeaturesSafety should always be a priority, and cutting torches come with features like flashback arrestors and check valves to help prevent dangerous situations. These features stop flames or gases from traveling back into the hoses, reducing the risk of fire or explosion. If you’re a casual user or less experienced, torches with built-in safety features are highly recommended. Even for professionals, these features add a reliable extra layer of protection.

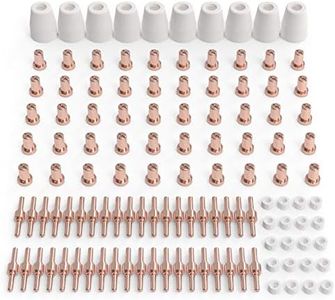

Ease of Adjustment and MaintenanceBeing able to easily adjust the flame and maintain your torch ensures good performance and safety over time. Some torches let you quickly change tips or adjust gas flow with simple controls, which is helpful if you need to switch between different jobs or materials. If you want hassle-free operation, look for torches that are easy to clean, have accessible parts, and clear instructions for maintenance.