We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

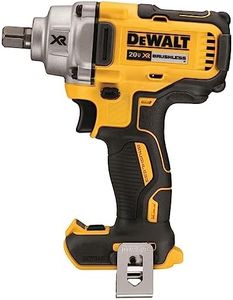

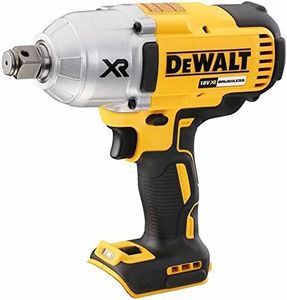

10 Best DeWalt Impact Wrenches

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best DeWalt Impact Wrenches

Choosing an impact wrench can make a big difference in how easily you can tackle tasks that require loosening or tightening bolts and nuts, especially in automotive work, construction, or heavy equipment maintenance. The right model can save you time, spare your hands, and improve your results. When shopping for an impact wrench, getting familiar with the main specifications will help you match the tool to your needs, so you get both power and convenience without going overboard or falling short.Drive SizeDrive size refers to the diameter of the square drive where you attach sockets, commonly found in sizes like 1/4-inch, 3/8-inch, 1/2-inch, and sometimes larger for heavy-duty models. This spec is important because it determines what size of sockets you can use and what kind of work the tool is suited for. Small sizes, like 1/4-inch and 3/8-inch, are best for lighter, precision tasks such as assembling furniture or working with smaller bolts. The 1/2-inch drive is the most versatile and popular for automotive and general household tasks, striking a good balance between power and manageability. Even larger sizes are meant for industrial or heavy machinery work. Choose a drive size that matches the types of projects and fasteners you mostly encounter.

Torque RatingTorque rating tells you how much turning force the wrench can deliver, usually measured in foot-pounds (ft-lbs) or Newton-meters (Nm). Higher torque means the tool can handle tougher, more stubborn bolts, while lower torque is suitable for lighter jobs. Torque ratings for impact wrenches often range from around 100 ft-lbs for light duty up to over 1,000 ft-lbs for heavy-duty models. If you'll be working mostly with cars, tires, or heavy equipment, you’ll want higher torque. If your tasks involve light assembly or delicate fasteners, lower torque is more suitable to avoid overtightening or damaging the material. So, consider the toughest job you plan to tackle, and make sure your wrench's torque matches or slightly exceeds what you'll need.

Power Source (Corded, Cordless, Pneumatic)The power source specification tells you whether the tool runs on batteries (cordless), plugs into the wall (corded electric), or is powered by compressed air (pneumatic). Cordless models are highly mobile and convenient, ideal if you need to move around or work in different locations. Corded models offer steady, unlimited run time but need to be near an outlet, making them suitable for workshop environments. Pneumatic models require an air compressor and are standard for professional shops, delivering high power and durability but at the cost of extra setup and less mobility. The right choice depends on where and how often you’ll be using your impact wrench, and what equipment you already have.

Weight and ErgonomicsWeight and ergonomics refer to how heavy the tool is and how comfortably it fits and feels in your hand. This is important because using a heavy or awkwardly-shaped tool for extended periods can cause fatigue and make precise work difficult. Impact wrenches can be under 3 pounds for compact models or over 7 pounds for heavy-duty ones. If you expect to use the tool for long periods or overhead tasks, choose a lighter, more ergonomic model. If occasional use is expected or strength is not a concern, a heavier model may not be an issue.

Speed and Impacts Per Minute (IPM)Speed is typically given in revolutions per minute (RPM), while impacts per minute (IPM) measure how many times the hammer mechanism inside the tool strikes in a minute. Higher RPM and IPM mean the tool can work faster and is more effective at loosening stubborn fasteners. For occasional use or light-duty projects, moderate speed and impact is sufficient. If time is a factor or you often deal with rusted or stuck bolts, look for higher RPM and IPM numbers. Just remember that more power and speed can also mean less control for delicate tasks, so match this to the precision and tempo required in your work.