We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Diamond Blade For Granite

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Diamond Blade For Granite

Choosing the right diamond blade for cutting granite is essential for safety, efficiency, and achieving the best possible finish. Granite is a tough, dense natural stone, so not all blades will perform the same. Understanding the blade's specifications helps you avoid issues like slow cutting, quick wear-out, or chipped edges. Always match the blade’s features to your project size, material type, and equipment.Blade DiameterBlade diameter refers to the size of the circular blade, typically measured in inches or millimeters. This size impacts how deep you can cut and what tools the blade will fit. Small blades (4-7 inches) are common for handheld tools and lighter jobs, offering more control and maneuverability, while larger blades (8-14 inches or more) are used on table saws or bridge saws for deeper and longer cuts. To choose the right one, consider the type of saw you have and the thickness of the granite to ensure the blade can handle the cut in a single pass.

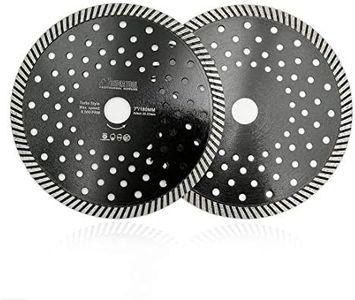

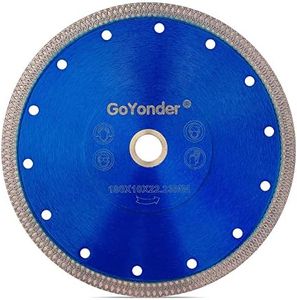

Segment TypeThe segment type refers to the design of the cutting edge where the diamonds are embedded. Common types include continuous rim, segmented rim, and turbo. Continuous rim blades provide smooth, chip-free cuts and are best for wet cutting. Segmented blades have breaks in the diamond rim for faster, rougher cuts and better cooling; they are suited for dry cutting and heavier-duty tasks. Turbo blades combine both, featuring a serrated edge for faster but still smoother cuts. The right segment type depends on whether you value speed, finish quality, or flexibility between wet and dry cutting.

Diamond Grit Quality and ConcentrationDiamond grit quality and concentration refer to how sharp the diamonds are and how densely packed they are along the cutting edge. Higher-quality, more concentrated diamond segments cut faster and last longer but may be overkill for occasional use. Lower concentrations wear out quicker but are fine for light, one-time jobs. Frequent users or those working on thick or very hard granite should seek high-quality, high-concentration blades for efficiency and durability.

Blade Bond HardnessBond hardness is about the material that holds the diamonds in place. Softer bonds release worn diamonds quickly, exposing fresh ones for cutting hard materials like granite. Harder bonds hold diamonds longer, which is better for softer materials but leads to slower cutting with granite. For granite, a blade with a softer bond is ideal, ensuring the blade stays sharp as it cuts through the tough stone.

Wet vs. Dry UseSome diamond blades are made strictly for wet use, some for dry, and others can handle both. Wet cutting uses water to cool the blade, reduce dust, and provide smoother results, which is especially important with granite as it prevents overheating and extends blade life. Dry use is more convenient for quick or remote jobs but risks more dust and blade wear. Always check whether your equipment and workspace can handle water and select accordingly, but for longer or more precise granite cuts, a wet-use blade is usually the safer and cleaner choice.

Arbor SizeArbor size is the diameter of the central hole in the blade that mounts onto your saw. It needs to match your saw’s spindle for proper and safe installation. Standard sizes often include 5/8 inch, 1 inch, or 20mm, but always check your tool’s requirements. Using the wrong arbor size can lead to unsafe or unstable operation, so it’s important to match the blade exactly to your saw’s specifications.