We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Diamond Drill Bit For Porcelain Tile

From leading brands and best sellers available on the web.Buying Guide for the Best Diamond Drill Bit For Porcelain Tile

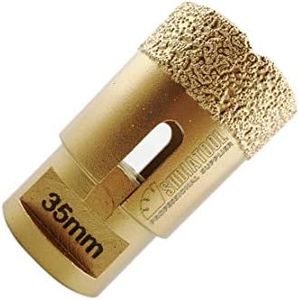

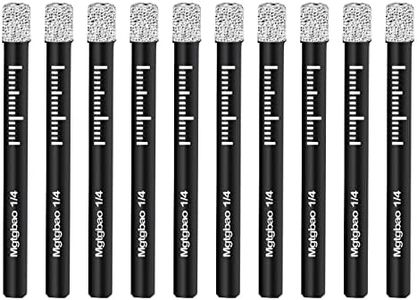

Choosing the right diamond drill bit for porcelain tile can make a big difference in the ease and success of your project. Porcelain is a hard and brittle material, so you need a drill bit that is both tough and precise. It's essential to consider what size hole you need, how often you will use the drill bit, and the nature of the project (such as installing fixtures or running pipes through tile). By focusing on the right features, you’ll avoid wasted time, damaged tiles, or broken drill bits.DiameterThe diameter is the width of the hole the drill bit will create. This is crucial because different tasks require different hole sizes, from small anchor holes for screws to larger openings for pipes or fittings. Drill bits often range from a few millimeters up to several centimeters in diameter. For most home improvement jobs, determine what needs to pass through the tile and pick the diameter accordingly. Measure your anchors, screws, or pipes and choose a bit that's just slightly larger to allow for easy fitment, but not so big that hardware is loose.

Diamond Coating QualityDiamond coating refers to the layer of industrial diamonds fixed to the tip of the drill bit. A good diamond coating is what helps the bit cut through tough porcelain without overheating or wearing down quickly. Coating quality can vary: entry-level bits may have a thin or uneven layer, while higher-quality bits use denser, more uniform coatings. If you have multiple or large projects, or the tiles are especially thick or hard, prioritize a bit with better coating quality to ensure a cleaner cut and longer lifespan. For single, simple jobs, basic bits can suffice, but for frequent or challenging work, always opt for higher-quality coating.

Bit Type (Core vs. Solid)There are two main types: core bits, which have a hollow center, and solid bits, which are fully solid. Core bits excel at cutting larger holes cleanly and efficiently, removing a 'plug' as they drill, and are especially suitable for pipes or fixtures. Solid bits are better for small holes but can wear out faster and may not perform as cleanly on porcelain. Your choice depends on the hole size and purpose; use solid bits for small holes (like screws), and core bits for larger requirements.

Cooling Method RequirementCutting through porcelain generates a lot of heat, which can damage both the tile and the bit. Some bits require water or a cooling system during use to control heat, while others can handle dry drilling for short periods. Using water-cooled bits can prolong tool life and help achieve a smooth finish, but it can be messier. If you’re working indoors or need a cleaner setup, look for bits designed for dry use, but be sure to limit use in one spot to prevent overheating. For longer or more precise jobs, water cooling is always safer.

Shank CompatibilityThe shank is the part of the drill bit that fits into your drill. Shanks can be round, hexagonal, or SDS, and must match your drill’s chuck. Using a mismatched shank can lead to poor performance or safety risks. Before buying, check your drill’s chuck type and size, and make sure the bit is compatible. This ensures the bit will stay secure while you drill and reduce the chances of slippage or breakage.