We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Dovetail Jigs

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Dovetail Jigs

Choosing the right dovetail jig is essential if you want to achieve strong, beautiful, and precise joinery in woodworking projects like drawers, boxes, and cabinets. Dovetail jigs help guide your router so that the pins and tails of your dovetail joints line up perfectly. When selecting a dovetail jig, it's important to consider your level of experience, the types of projects you want to tackle, and how versatile you need the tool to be. Understanding the most important features will help you choose a jig that suits both your current and future woodworking needs.Maximum Board Width CapacityThe maximum board width capacity describes the widest workpiece the dovetail jig can handle. This spec is very important because it determines the size of the boards you can join using the jig. Smaller jigs may handle pieces up to 12 inches wide, which is sufficient for many drawers or small boxes, while larger jigs can accommodate much wider boards for bigger projects like cabinets or furniture. When choosing the right width capacity, think about the largest projects you plan to work on, and make sure the jig you select can handle those boards comfortably. Generally, investing in a jig with a bit more capacity than you currently need can help future-proof your setup.

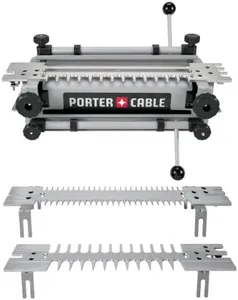

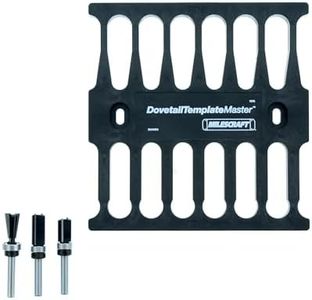

Types of Joints SupportedDovetail jigs can vary in the types of joints they produce: through dovetail, half-blind dovetail, sliding dovetail, and even box/finger joints. This is important because the joint style affects both the strength and the appearance of your work. Some jigs only support one type, while others are more versatile and allow for multiple styles using different templates. To navigate this, consider which joints are most beneficial for your main projects—half-blind dovetails are classic for drawers, while through dovetails are visible on box corners. If you want flexibility to experiment with different styles, look for a jig that supports various joint types.

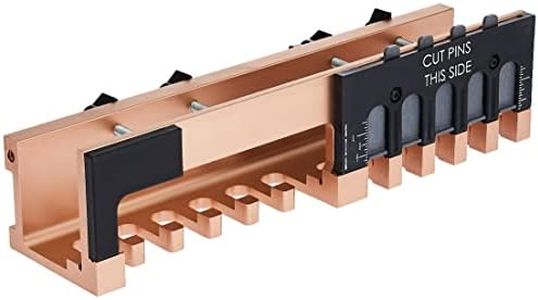

Template Material and DurabilityTemplates are the parts of the jig that guide your router, and they can be made of materials like aluminum, steel, or plastic. Strong and durable templates are critical for accuracy and longevity, especially if you plan on using the jig frequently. Aluminum and steel offer long life and resist wear, making them well-suited for heavy use, while quality plastics can be fine for occasional or hobbyist tasks at a lighter cost and weight. Your choice should depend on how often you plan to use the jig and whether you value durability or lightweight design more.

Ease of Adjustment and SetupThis refers to how simple it is to set up the jig and make precise adjustments in depth, spacing, and alignment. User-friendly jigs with clear markings, tool-free adjustments, and straightforward clamping can save time and reduce frustration, especially for those new to dovetailing. More complex jigs offer greater customization but can take longer to adjust and have a steeper learning curve. If you’re a beginner, prioritizing easy setup can make the learning process smoother, while experienced woodworkers may prefer more control and flexibility even if setup is more involved.

Clamping SystemThe clamping system secures your workpiece and ensures it won't move during routing. Reliable clamping is essential for safety and for achieving accurate, tear-free joints. Some jigs have simple cam clamps, while others have more robust mechanisms or even integrated vises. For smaller or thinner pieces, simpler clamping systems often suffice, but if you work with heavy or large boards, a stronger and more versatile clamping system is crucial to avoid mistakes. Consider what size and thickness of lumber you will typically work with to determine how robust your clamping needs to be.