We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Dremel Drill For Sea Glass

From leading brands and best sellers available on the web.Buying Guide for the Best Dremel Drill For Sea Glass

When it comes to picking a Dremel-type drill for working with sea glass, it's important to think about what you'll be using the tool for most often. Sea glass can be delicate, and requires both precision and care, so your tool should be easy to handle, offer the right amount of power, and support the bits you’ll need for glass work. Take note of comfort, ease of use, and the specific features that will make your crafting enjoyable and safe.Speed Control (RPM)Speed, measured in RPM (revolutions per minute), tells you how fast the drill spins. This is important because different materials and tasks call for different speeds; too high a speed on delicate sea glass could cause cracks or chips. Dremel-style tools often come in single-speed or variable-speed models. Single-speed tools are straightforward but less flexible, making them better for simple or routine work. Variable-speed tools let you adjust how fast the drill spins, which is ideal for sea glass, as you can start slow for precision and increase speed for efficiency. For most hobbyists, choosing a tool with variable speed means more control and better results, especially when working on delicate projects like sea glass drilling.

Power Source (Corded vs. Cordless)The power source determines whether the tool requires plugging into a wall (corded) or runs on batteries (cordless). Corded drills provide consistent power for long periods but need an outlet nearby, which can be limiting in terms of mobility. Cordless models offer freedom to move and are great for working outdoors or in different places, but they have limited battery life and may not match corded models for continuous use. If you expect to work for long sessions or need consistent power, corded may suit you. If you want maximum portability or easy storage, cordless is a good choice, especially for smaller, shorter sea glass projects.

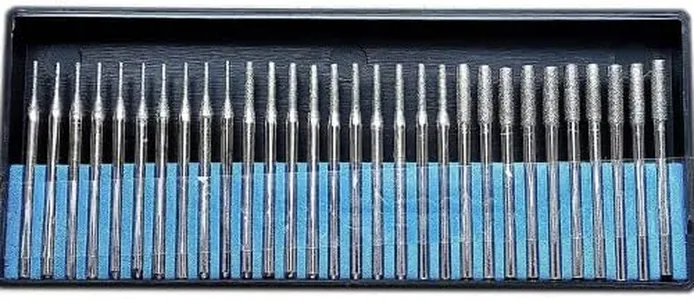

Collet Size/Bit CompatibilityCollet size refers to the size of the opening where you insert drill bits. This is key for sea glass drilling, as you will need to use specific diamond or carbide bits designed for glass. Common collet sizes include 1/8 inch and 3/32 inch. Choosing a drill that fits a range of bit sizes means more flexibility for your projects. If you already know the type of bits you prefer, make sure your tool can accommodate them. For most sea glass craftwork, a tool supporting small-diameter bits is preferable for delicate, precise holes.

Ergonomics and WeightErgonomics refers to how comfortable and easy the tool is to hold and control. This is especially important when working with sea glass, where careful handling is essential to avoid cracks. Lighter models are generally easier to maneuver, reduce hand fatigue, and make it possible to work on fine details for longer periods. If you have smaller hands or plan on doing lots of intricate work, prioritize a slim, lightweight, and well-balanced tool that fits comfortably in your grip.

Accessory Availability and Water CompatibilityFor drilling sea glass, you’ll need access to specialized accessories like diamond-coated drill bits and possibly water attachments (as water is often used to cool the glass and the bit, reducing heat and preventing glass from breaking). Make sure the tool is compatible with these accessories, and that it's easy to swap them out as needed. Some kits also include splash guards or attachments that help keep water contained. If you’re just starting out, look for a tool that supports easy accessory changes and has basic water-compatible attachments available.