We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

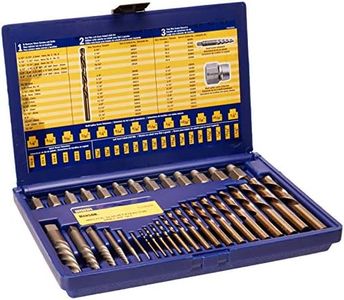

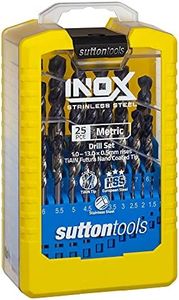

10 Best Drill Bits

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Drill Bits

Choosing the right drill bit is essential for making clean, accurate holes and for preserving the life of both your drill and work material. The main factors to consider are the material you'll be drilling into, the size of the hole you need, and whether you need specialty bits for unique tasks. It's important to match the bit to your project needs – using the wrong bit can make your work harder or even damage your materials or tools. By understanding the main specifications, you can confidently select the best drill bits for any job around the home or workshop.MaterialMaterial means what the drill bit itself is made out of, and it's a critical factor because it impacts the bit’s strength and what materials it can effectively drill through. High-speed steel (HSS) is a common all-round choice for wood and soft metals. Cobalt and carbide-tipped bits are tougher and withstand heat better, making them ideal for harder metals and masonry. Black oxide or titanium-coated bits offer extra durability and corrosion resistance. If you'll mostly be drilling wood or plastic, standard HSS works well. For frequent metal work or tougher applications, consider cobalt or carbide bits.

Bit TypeBit type refers to the shape and design of the bit’s tip and body, each tailored for specific hole shapes or materials. Twist bits are the standard all-purpose choice, suitable for many jobs. Spade bits are flat and wide, excellent for quickly drilling larger holes in wood. Masonry bits have reinforced, often pointed tips for use in brick, concrete, or stone. For drilling holes in glass or tile, look for spear-point glass bits. Choosing the right bit type depends on your job – use the bit specifically designed for your material to get cleaner results and to work more easily.

Size (Diameter)Diameter is the measurement across the widest part of the bit, indicating the size of the hole it will create. Drill bits are available in a wide range of sizes, typically measured in millimeters or inches. Smaller diameters (under 3mm) are great for pilot holes and precise work, while medium sizes (3–10mm) cover many general tasks like hanging shelves or screwing in hardware. Larger bits (over 10mm) are best for big holes, like running pipes or cables. Always check the hole size needed for your project, and use a bit that matches or is slightly smaller than the fastener or anchor you’re using.

LengthLength refers to how long the drill bit is, which impacts how deep you can drill. Standard length bits handle most everyday tasks, but extended or extra-long bits are available if you need to drill deeper holes, like running wires through studs or thick materials. However, longer bits can be harder to control and may bend if not used carefully. If most of your projects are fairly routine, regular-length bits are sufficient, but if you anticipate needing to reach into deep or hard-to-access areas, a few longer bits could be useful.

Shank TypeShank type is about the shape of the end of the bit that fits into the drill. The most common are round shank (for standard chucks) and hex shank (for quick-change or impact drivers). Hex shanks are less likely to slip in the drill and allow for fast swapping. If you use a regular drill, either type will work, but for cordless drivers or quick-change chucks, hex shank bits make your work more efficient.

CoatingCoating refers to the surface treatment on the drill bit and it can affect both durability and performance. Uncoated bits are economical but may wear quickly. Black oxide and titanium coatings are popular for improved resistance to heat and rust, which is especially good if you use your bits often or drill into tough materials. If you work with hardwood, metals, or in damp conditions, a coated bit can save you time and replacements. For occasional use in soft materials, coating isn’t as critical.