We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

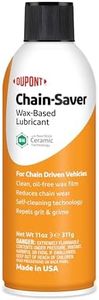

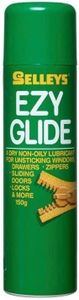

10 Best Dry Lubricant Spray

From leading brands and best sellers available on the web.Buying Guide for the Best Dry Lubricant Spray

When choosing a dry lubricant spray, it's important to think about where and how you plan to use it. Dry lubricants are popular for their ability to reduce friction without leaving sticky or oily residues. This makes them great for applications where clean, dust-free performance is needed, like on locks, hinges, or bike chains. Understanding the main features to look out for will help you choose the right product for your needs.Lubricant Base MaterialThe base material of a dry lubricant spray is what actually performs the lubrication. Common bases include PTFE (like Teflon), graphite, or silicone. PTFE works well for most surfaces and provides excellent low-friction performance. Graphite is ideal for locks and mechanisms exposed to cold or dust, while silicone is versatile and safe for use on rubber or plastic. Understanding what you'll be lubricating will help you pick the base that best matches your application: PTFE for general use, graphite for locks or dusty areas, and silicone for mixed materials.

Drying TimeDrying time refers to how long the spray takes for the solvent or carrier to evaporate, leaving just the lubricating layer. Fast-drying sprays are best when you need to use the item quickly after lubrication, while sprays that take longer to dry may penetrate deeper, which can be good for tight spaces. If you're treating items you need to use immediately, look for a spray with a short drying time.

ResidueA key advantage of dry lubricants is that they leave behind minimal residue, but the type and visibility of residue can vary. Some may leave a visible film, while others are nearly invisible. For applications where appearance or cleanliness matters, such as in homes or offices, choose a spray that promises a clear, non-sticky finish.

Application MethodDry lubricant sprays can come with different nozzle designs, such as straws for precise application or wide sprays for covering larger areas. If you plan to lubricate small or hard-to-reach parts, look for a spray with a thin straw. For larger surfaces, a wide-spray nozzle might be more practical.

Surface CompatibilityNot all dry lubricants are safe for all materials. Some formulas may work best on metal, while others are safe for plastic, rubber, or wood. It's important to check which surfaces the lubricant is designed for to avoid damaging the item you're working on—especially for electronics, plastics, or painted surfaces.

LongevityLongevity describes how long the lubricant continues to reduce friction after application. Some sprays are designed for frequent reapplication and are ideal for items that see repeated or aggressive use. Others are more long-lasting, requiring less frequent use. If you're lubricating parts with high wear rates or exposure to the elements, consider a spray designed for extended protection.