We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

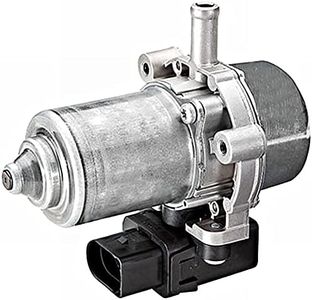

10 Best Electric Vacuum Pump For Brakes

From leading brands and best sellers available on the web.Buying Guide for the Best Electric Vacuum Pump For Brakes

When you're shopping for an electric vacuum pump for brake systems, it's important to focus on your vehicle's requirements and the demands of your braking system. The vacuum pump's main job is to provide sufficient vacuum pressure to operate brake boosters, especially in cars with engines that don't naturally produce enough vacuum, such as turbocharged, supercharged, or diesel engines. By understanding your driving habits, vehicle setup, and installation preferences, you can narrow down the right product that will deliver safe, efficient braking performance.Vacuum Pressure OutputVacuum pressure output, usually measured in inches of mercury (inHg) or kilopascals (kPa), refers to how much vacuum the pump can generate. This is crucial for proper booster operation, as insufficient vacuum can lead to a hard brake pedal or insufficient braking force. Most basic vehicle systems need a vacuum in the range of 15-20 inHg. Lighter, smaller engines can get by with values on the lower end, while larger or more demanding brake setups benefit from pumps that can provide higher vacuum levels. Choosing the right pressure depends on your vehicle's needs; check your brake booster’s requirements or your owner's manual, and aim for a pump that meets or slightly exceeds that value.

Pump Flow RateThe flow rate, often measured in liters per minute (L/min), indicates how quickly the pump can draw air out of the system. A higher flow rate results in faster vacuum build-up, especially noticeable if the brake booster frequently loses vacuum or in heavy-use situations. Low-flow pumps work fine for standard daily driving, but if you have power-hungry accessories, a larger engine, or use your brakes aggressively and often, a higher flow rate ensures the system keeps up with demand.

Duty CycleDuty cycle means how long the pump can operate continuously without overheating or failing and is usually given as a percentage (like 50% or 100%). A lower duty cycle is fine for vehicles where the pump only runs occasionally, but if your booster loses vacuum frequently or you drive in a way that requires constant replenishing, look for a pump with a higher or even continuous (100%) duty cycle to avoid premature wear or shutdowns.

Noise LevelNoise level refers to how loud the pump is during operation. Electric vacuum pumps can vary from almost silent to noticeably loud. For most drivers, a quieter pump is more comfortable, especially if it's mounted inside the cabin or near passenger areas. If noise bothers you, check the decibel (dB) rating or look for noise-dampening features. For underhood installations, noise might be less of a concern.

Size and Mounting OptionsThe physical size of the pump and the way it mounts are important for installation. Small, compact pumps fit well in tight engine bays, while larger pumps may offer better performance but need more room. Some pumps come with mounting brackets or kits for universal installation, while others are designed for specific vehicle types. Consider your vehicle's available space and pick a pump that can be securely installed in the desired location.

Power Source and WiringElectric vacuum pumps require a power connection, usually to the vehicle's 12V system. Some are simple two-wire setups, while others have additional wiring for relays, sensors, or switches. Simpler wiring is easier for DIY installs. Make sure that your electrical system can handle the pump’s power consumption, and that installation instructions match your skills or the help you have available.

Additional FeaturesSome pumps offer extra features like integrated check valves, pressure switches, or vibration isolation. These can enhance performance or make installation easier. Check valves ensure vacuum is held when the pump turns off, while pressure switches automate the pump's on/off cycles. Vibration isolators reduce noise and wear. Decide which features matter most based on your installation goals and ease of use.