We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

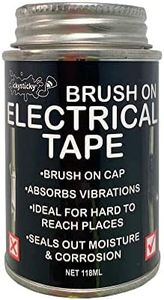

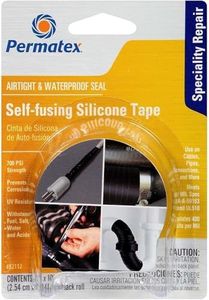

10 Best Electrical Tapes

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Electrical Tapes

Choosing the right electrical tape is all about matching the tape’s properties with your intended use. Electrical tape is used mainly for insulating electrical wires and other materials that conduct electricity, but it’s also handy for color coding, repairs, and bundling. The best fit for you will ensure safety, compatibility with your project, and long-lasting results. Understanding a few key specifications will help you make the right choice for your needs.MaterialMost electrical tapes are made of vinyl, but there are also options in rubber and other synthetic materials. The material determines the tape’s flexibility, strength, and resistance to factors like moisture, heat, and chemicals. Vinyl is the most common for general electrical insulation because it’s both flexible and durable. Rubber tapes are used when higher insulation or heat resistance is needed, while specialty synthetic options might offer properties like flame retardance. Choosing the right material depends on whether you need standard insulation for home wiring (vinyl works great) or special resistance for high temperatures or challenging environments (look for rubber or specialty tapes).

Adhesion StrengthAdhesion strength refers to how well the tape sticks to surfaces, especially wires and cables. Stronger adhesion is important for places where the tape might be under strain or exposed to movement, moisture, or dust. For most home and simple electrical repairs, medium adhesion suffices, sticking well without being difficult to remove. For outdoor, automotive, or industrial work where conditions are tough, high adhesion strength is preferred. Always think about if the tape will move or if it needs to stay put over time, and pick accordingly.

ThicknessThickness, usually measured in mils (thousandths of an inch), affects both the insulation ability and durability of the tape. Thinner tapes (around 5-6 mils) are easy to wrap around tight curves and are fine for low-voltage jobs. Medium thickness (7-8 mils) provides a balance between flexibility and protection, making it ideal for most electrical work. Thicker tapes (above 8 mils) offer extra mechanical protection and insulation, useful for heavy-duty or outdoor tasks. Decide on thickness based on whether you need extra strength or if your project has tight spaces requiring flexibility.

Temperature RatingTemperature rating shows the range of temperatures where the tape will perform well without melting, hardening, or losing stickiness. Lower temperature-rated tapes (up to 80°C/176°F) are suitable for most indoor electrical repairs. If you’re working in areas with higher heat, like engine bays or outdoor locations, look for tapes with a higher rating (above 105°C/221°F). Consider the environment the tape will face to pick a rating that ensures reliability and safety.

Voltage RatingVoltage rating tells you the maximum voltage the tape can effectively insulate against. Lower-rated tapes are fine for low-voltage projects like speaker wire, while higher-rated tapes are necessary for standard house wiring or industrial uses. Always check the insulation voltage of your project and choose a tape with a rating that matches or exceeds it for safety.

ColorElectrical tapes come in a variety of colors, with black being standard for insulation, while other colors are used for phase identification or coding wires. Color can help you stay organized and make future work easier. Pick your color based on whether you need to identify wires by function, or just need a general-purpose tape.