We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

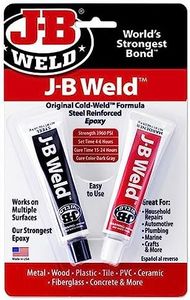

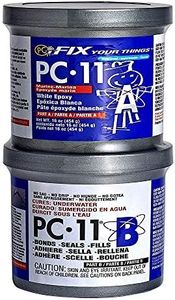

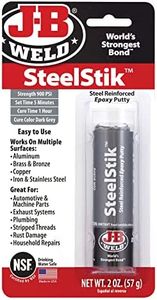

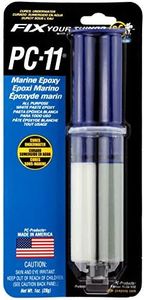

10 Best Epoxy For Aluminum

From leading brands and best sellers available on the web.Buying Guide for the Best Epoxy For Aluminum

Choosing the right epoxy for aluminum is important to ensure strong, lasting bonds, especially because aluminum can be tricky for adhesives due to its smooth, often nonporous surface. Epoxy is a popular adhesive for aluminum because it forms a tough, long-lasting connection. The key to picking the best epoxy is to focus on your application—are you repairing something structural, sealing, or just doing some light-duty bonding? Understanding a few main specs will help match the epoxy’s strength, curing time, and ease of use to your project’s needs.Bond StrengthBond strength refers to how much force the cured epoxy can withstand before breaking apart. This is vital if your aluminum parts will face stress, weight, or pressure. Bond strength is usually measured in pounds per square inch (PSI). Low-strength epoxies (below 1000 PSI) are fine for crafts or non-load-bearing repairs, medium (1000–3000 PSI) is good for light to moderate duty, and high-strength epoxies (above 3000 PSI) are meant for structural repairs. To choose, consider how much stress or load the bonded area will face. If it’s just decorative or low-impact, lower bond strength is OK. If the bond will bear weight or vibration, opt for higher strength.

Cure TimeCure time is the amount of time it takes for the epoxy to fully set and reach its full strength. Some epoxies set in minutes (fast-cure), while others take hours or even overnight (slow-cure). Quick-setting epoxies are convenient for minor repairs or small jobs, while slow-curing types often form a stronger, more resilient bond, making them better for heavy-duty applications. Think about your workflow—if you want to reposition the parts or have a large area to cover, a slower cure gives more working time. For small, simple fixes, a fast cure works well.

Temperature ResistanceTemperature resistance is how well the epoxy can withstand heat or cold once cured. Some epoxies maintain their strength at very high or low temperatures, while others can soften or break down. If your aluminum item will be exposed to high heat (like engine parts or outdoor settings), make sure to pick an epoxy rated for higher temperatures, often above 200°F (93°C). For typical indoor use, standard temperature resistance is usually enough. Always match the epoxy’s temperature rating to where and how the bonded part will be used.

Water and Chemical ResistanceThis spec tells you how well the cured epoxy defends against water, oils, solvents, or chemicals. For outdoor, marine, or kitchen/bathroom use, water and chemical resistance is essential to prevent the bond from breaking down over time. Some epoxies are specially formulated to withstand constant moisture or chemical exposure. Check this spec if your aluminum piece will be regularly exposed to any kind of liquids or harsh substances. If your project is for dry, indoor use, you might not need high resistance.

Workability (Viscosity and Mix Ratio)Viscosity refers to how thick or runny the epoxy is when mixed. Thicker (high viscosity) formulas are good for filling gaps and vertical surfaces, while thinner (low viscosity) ones spread easily for thin joints. The mix ratio tells you how to combine resin and hardener, and some epoxies are easier to mix than others. For intricate or overhead work, pick a thicker epoxy to control drips. For smooth, flat surfaces or close-fitting parts, a thinner epoxy works best. Always check instructions for mix ratio to ensure best performance.

Surface Preparation RequirementsSome epoxies require more surface preparation than others to ensure a solid bond. This could mean roughening the aluminum, cleaning off oil or oxidation, or using a special primer. If you want a quick process and are okay with a slightly weaker bond, look for epoxies that are more forgiving. For maximum strength, be prepared to thoroughly clean and possibly sand the aluminum surface. Match your willingness and ability to prep the metal with the epoxy’s requirements for a successful bond.