We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Flux Core Wire

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Flux Core Wire

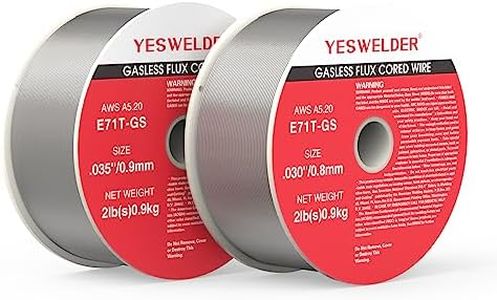

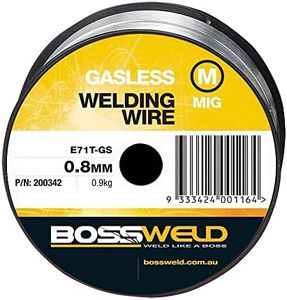

Choosing the right flux-core wire is essential for getting good welding results, especially if you're working without shielding gas or in outdoor conditions. The right wire can impact the strength, appearance, and ease of your welds. When picking a flux-core wire, you'll want to think about what kinds of materials you’re joining, whether your project is indoors or outdoors, and your welding machine’s capabilities. Taking a closer look at the key specifications of flux-core wire will help ensure you match the product to your job and get strong, clean welds.Wire DiameterWire diameter refers to the thickness of the flux-core welding wire and typically comes in sizes like 0.030”, 0.035”, or 0.045”. This is important because different diameters are suited for different tasks; thinner wires work better on lighter materials and make it easier to weld with lower-powered machines, while thicker wires are used for heavier plates and higher currents. If you're mostly fixing thin sheet metal or doing small jobs, a thinner wire helps avoid burning through your work. For thick steel or heavy-duty projects, thicker wire provides deeper penetration and stronger welds.

Wire Type (Self-Shielded vs. Gas-Shielded)Flux-core wires come in two main types: self-shielded and gas-shielded. Self-shielded wires do not need any extra shielding gas and are great for outdoor or windy conditions because the flux in the core creates its own protective gas. Gas-shielded wires, on the other hand, rely on an external gas supply and tend to make cleaner welds with less spatter, but they need you to work indoors or in sheltered spaces. For outdoor repairs or places where bringing a gas cylinder is tricky, self-shielded wire is best. For shop work where weld appearance matters, gas-shielded wire could be the right choice.

Material CompatibilityFlux-core wires are often designed for specific types of metals, most commonly mild steel, though there are options for stainless steel or other alloys. Matching the wire to the metal you’re welding is crucial; using the wrong wire can cause weak welds or poor bonding. Always check that your chosen wire states which materials it works with and pick a wire specifically intended for the kind of metal you’re joining.

Tensile StrengthTensile strength, usually measured in pounds per square inch (psi), tells you how strong and durable the weld will be. Higher values mean the weld can handle more stress before breaking. This matters most for structural projects or anything that needs to be very sturdy; if your weld will be holding weight or under pressure, choose a wire rated for higher tensile strength. For basic repairs or non-load-bearing welds, standard strength is often enough.

Spool SizeSpool size refers to how much wire is included on each roll. Spools range from small 1-pound rolls for light work or occasional use to large 10-, 20-, or 33-pound rolls designed for bigger projects and less frequent wire changes. If you're a hobbyist or only planning a small job, a small spool is easy to handle and store. For frequent use or larger projects, bigger spools save money in the long run and reduce the hassle of changing wire often.