We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

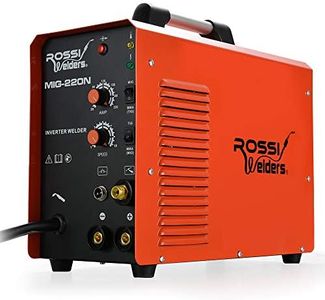

10 Best Gasless Mig Welder

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Gasless Mig Welder

Choosing a gasless MIG welder can feel overwhelming with all the technical jargon, but making the right choice really comes down to understanding what you'll be welding, how often you'll use the machine, and where you'll be working. It's important to compare a few core specifications so you can match the welder's capabilities to your specific needs. By recognizing what each spec means and how it translates to real-world performance, you'll be far more confident in picking a welder that's reliable, easy to use, and right for your tasks.Amperage RangeAmperage range tells you how powerful the welder is and what kind of metal thickness it can handle. Lower amps are suitable for thinner metal, while higher amps are needed for thicker pieces. Generally, if you're planning to do light repairs or automotive work, a lower end of the amperage scale will do the job; for heavier construction or thicker stock, look for a machine with a higher maximum amperage. Knowing the typical thickness and type of metal you'll weld will help you decide which amperage range you'll really use.

Duty CycleDuty cycle refers to how long the welder can operate within a 10-minute period before it needs to cool down. For example, a 20% duty cycle at a certain amperage means you can weld for 2 minutes and then let it rest for 8 minutes. If you expect to weld in short, occasional bursts, a low duty cycle is fine. For longer projects with fewer breaks, look for a higher duty cycle at your preferred amperage. Consider how much continuous work you'll need to do—this will guide you to the right duty cycle.

Input VoltageThe input voltage tells you what kind of power the welder needs. Many gasless MIG welders work on standard household power (like 120V), while larger units may require 240V outlets. If you plan to use your welder at home or in places with standard outlets, a 120V model will be most convenient. However, for more demanding jobs or industrial settings, a machine that runs on 240V might be necessary. Always consider where you'll be plugging in the welder when making your choice.

Wire Feed Speed ControlWire feed speed control allows you to adjust how quickly the welding wire comes out of the gun. This impacts your control over the weld and the quality of the finished job. Some welders offer a wide, finely adjustable range, while others have fewer settings. For beginners or those working with different materials, an easily adjustable, wide-range wire feed will help you dial in the sweet spot for each task. The more variety of projects you foresee, the more flexible you’ll want the wire feed control to be.

Portability and WeightPortability and weight matter if you expect to move the welder around or work in different locations. Lighter, compact machines are easy to carry and store, making them great for mobile work or tight spaces. Heavier welders can be more stable for bench work but may be inconvenient to transport. Think about where you'll typically use the welder and how much moving it'll require—a lighter unit is often best for DIY and home use, while a heavier model might suit fixed workshop setups.

Thermal Overload ProtectionThermal overload protection is a safety feature that prevents the welder from overheating. When the internal temperature gets too high, this system automatically shuts the machine off to avoid damage. If you’re new to welding or expect longer sessions, this feature adds peace of mind and extends the welder’s lifespan. Anyone can benefit from this, but it’s particularly valuable for beginners or settings where the welder might be pushed to its limits.