We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

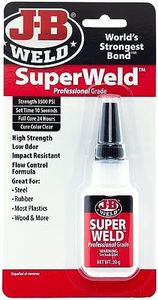

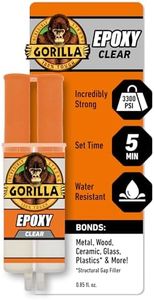

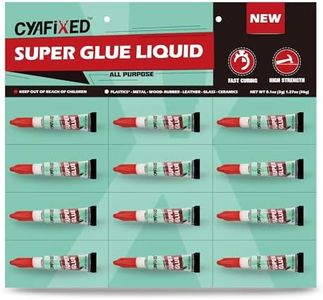

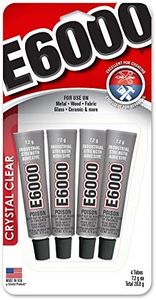

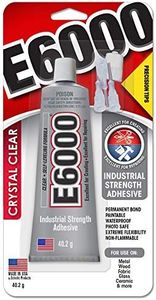

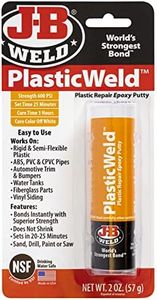

10 Best Glue For Plastics

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Glue For Plastics

When you’re shopping for glue to use on plastics, it’s important to recognize that not all adhesives are created equal. Different glues work with different types of plastics and for different purposes: some are best for crafts, others for repairs, and some for industrial use. Your selection should be based on what plastic you’re working with and what you need the glue to do – whether it needs to hold under stress, resist water, or remain invisible. Carefully reading labels and matching the glue’s properties to your project needs will lead to the best results.Type of GlueThe type of glue refers to the chemical formula that enables it to bond plastics. Common types include cyanoacrylate (super glue), epoxy, plastic cement (solvent-based), and polyurethane. Each glue type interacts with plastics differently—for instance, plastic cement softens the surface and fuses it, while super glue forms a quick surface bond. Knowing the type is important because some plastics (like polyethylene and polypropylene) are resistant to standard adhesives. If you want a quick fix, super glue might suffice, but for a strong, durable repair or joining two different plastic types, epoxy or plastic cement may be better.

Plastic CompatibilityThis refers to which plastic materials the adhesive works with, since 'plastic' covers many different chemical compositions. Not all glues bond well to all plastics; for example, some work great on ABS or PVC but not on PP or PE. Compatibility is key because using the wrong glue may result in a weak bond or no bond at all. Always check which plastics a glue is rated for, usually listed on the packaging, and match this to the item you want to fix or create.

Strength of BondBond strength determines how well the glue holds the pieces together under stress—like pulling, bending, or dropping. Bond strength can be categorized as low (for crafts and light applications), medium (for model building or household repairs), and high (for load-bearing repairs or automotive use). Think about the demands on the finished item: If it needs to withstand handling or weight, choose a glue noted for its high strength.

Drying/Curing TimeDrying or curing time is how long the glue takes to set or fully harden. Some glues set in seconds; others need hours to reach full strength. This matters for your workflow: fast-setting adhesives are great for quick jobs or small items, but slower-curing glues may provide a stronger or more reliable bond, particularly for large surfaces. Consider how much time you’re able to wait and how precise you need to be.

Water and Heat ResistanceWater and heat resistance refer to whether the glue will hold up in wet or warm environments. For items that will be used outdoors, in the kitchen, or around water, it’s critical to choose a glue designed to resist moisture and the temperatures it may encounter. If your project stays indoors and dry, this may be less important.

Clarity and FinishClarity and finish describe how the glue looks once dry. Some glues dry clear, others yellow or stay visible. For projects where looks matter—like repairing toys or crafts—choose a glue that dries clear or matches your plastic’s color. For structural or hidden repairs, this may not matter much.

Application MethodThe application method is how you get the glue onto your project. Tubes, bottles with precision tips, sprays, and dual-syringe dispensers are common. If you need neat, precise application (like on small or delicate parts), look for thin-tipped bottles; for big repairs, a thicker consistency or spreadable glue would be easier to manage.