We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Grease Gun Fitting

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Grease Gun Fitting

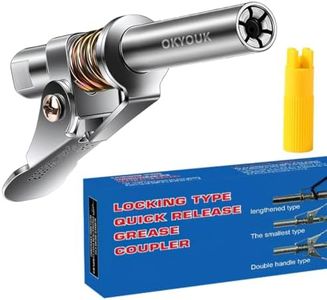

Choosing the right grease gun fitting is important for anyone doing maintenance on vehicles, machinery, or equipment. These small parts are what connect your grease gun to the grease nipple (also called zerk fitting) on the item you want to lubricate. A poor-fitting coupling can make greasing difficult, cause leaks, or even lead to equipment damage. When picking the best grease gun fitting, you want to pay attention to the type, size, ease of use, and build quality to make sure it matches your equipment and workflow. Consider the kind of machinery you service and think about the environments in which you’ll use the tool.Fitting TypeThe fitting type refers to the general design of the connector and the way it attaches to the grease nipple. Most common are standard couplers, locking couplers, and quick-connect fittings. Standard couplers are simple and usually suitable for basic greasing jobs. Locking couplers provide a tighter hold, so they won't pop off under pressure, which is helpful for high-pressure situations or awkward angles. Quick-connect fittings make swapping between tools faster. If you often find your fitting falling off, a locking or quick-connect style might be best. If your work is simple and direct, a standard coupler is often enough.

Thread Size and CompatibilityThread size determines whether the fitting can attach securely to your existing grease gun and the grease nipple. Common sizes include SAE or metric measurements, such as 1/8" NPT or M10x1. If the threading does not match, you won’t get a proper seal, making greasing frustrating or impossible. Check the equipment you’ll be servicing and your grease gun to find out what thread sizes are required. For universal compatibility, some people choose kits that include different adapters.

Material QualityGrease gun fittings are usually made of steel, zinc, or brass. Steel is strong and long-lasting, zinc can resist rust, and brass is softer but resists corrosion well. Material quality determines how long the fitting will last and how well it resists everyday damage and environmental hazards. For daily, rugged use or harsh environments, opt for steel or zinc-plated types. For less frequent or lighter-duty use, brass can work well and resists corrosion.

Pressure RatingPressure rating shows how much pressure the fitting can handle without breaking or leaking. Grease guns can produce significant pressure, so check that the fitting is rated for at least as much as your grease gun produces (often measured in PSI). Lower-pressure couplings risking popping off or leaking, especially on stubborn grease points. If you service heavy machinery or face tough fittings, prioritize a higher pressure rating. For casual or light use, a standard rated fitting should be fine.

Ease of UseEase of use involves how simply you can attach and detach the fitting, especially in tight or hard-to-reach spots. Some fittings have ergonomic grips, locking levers, or swivel heads for better access and comfort. If you work in cramped spaces or shift between many grease points, prioritize ergonomic, easy-to-use features. If greasing is infrequent or clear access is available, a basic fitting might suffice.