We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Heat Sealers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Heat Sealers

Selecting the right heat sealer is all about understanding your packaging needs and matching them to the right machine. Heat sealers are used to bond materials together using heat, often for closing bags or packaging items for freshness, protection, or presentation. Before making a choice, consider what you'll be sealing, how often you'll use the machine, and the environment it will be used in. This will help you narrow down the features and specifications that are most relevant for you.Sealing WidthThe sealing width refers to how wide the heat-sealed strip will be on your package. It's important because a wider seal typically means a stronger and more durable closure, which is particularly useful for heavy or bulky items, or for products that need to stay airtight or watertight. Heat sealers come with various sealing widths, often ranging from a few millimeters to a centimeter or more. For light products or small bags, a narrow seal is usually sufficient, while food packaging or industrial items may need a wider seal for security. Think about what you are sealing—if strength and protection are key, opt for a wider sealing width.

Seal LengthSeal length is the maximum length of the seal the machine can produce in one go. This is important if you want to seal bags of different sizes or work with a variety of package widths. Heat sealers are available with different lengths, commonly from about 20 cm up to 100 cm or more. To choose the right one, make sure the seal length is at least as wide as your largest package. If you mainly seal small bags, a shorter length will suffice, but if you work with large sacks or sheets, a longer seal length is essential.

Type of Sealer (Impulse vs. Constant Heat)There are two main kinds of heat sealers: impulse and constant heat. Impulse sealers only heat up when pressed down, which makes them energy-efficient and safer for most plastic bags. Constant heat sealers keep the sealing element hot at all times and are better for sealing materials that need higher temperatures, like cellophane or aluminum foil. This decision depends on the type of material you need to seal. For occasional or general plastic bag sealing, impulse sealers are ideal. For specialty materials or high-speed operation, consider constant heat models.

Adjustable Timing/Temperature ControlsTiming or temperature controls allow you to fine-tune how long and how hot the sealer operates during each seal. This is important because different materials and thicknesses require different sealing conditions for a reliable closure. Some heat sealers offer simple timer adjustments, while others provide more advanced temperature settings. If you seal a variety of bag types or materials, adjustable controls provide flexibility and consistent results. For sealing only one type of standard bag, basic settings may be enough.

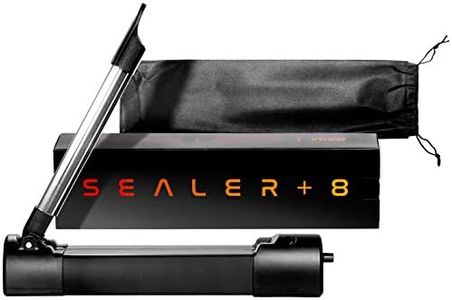

Portability and Build QualityPortability refers to how easy it is to move the unit around, while build quality speaks to the machine’s durability. Smaller, lightweight heat sealers are great for occasional or home use, easy to store and transport. Heavier-duty models are bulkier but offer more robust performance for commercial or frequent use. If your work area changes or you need to store the sealer between uses, portability is key. If you plan to use it in the same place regularly, sturdier build quality might be more important.