We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

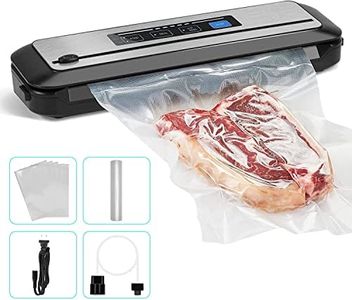

10 Best Heavy Duty Vacuum Sealer

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Heavy Duty Vacuum Sealer

When looking to buy a heavy-duty vacuum sealer, it's important to understand your needs—are you sealing large quantities for home use, hunting, fishing, or commercial purposes? Consider what kinds of foods or items you'll be sealing and how often you'll be using the machine. The right vacuum sealer will make your work easier, more efficient, and help preserve your items for much longer.Sealing Power (Vacuum Strength)Sealing power refers to how effectively the vacuum sealer can remove air from the bag before sealing it. This is important because stronger vacuum strength means better preservation by reducing oxygen exposure, which slows down spoilage. You’ll usually see this spec measured in terms like inches of mercury (inHg) or kilopascals (kPa). Lower values are fine for light, occasional use and deli meats, whereas higher values are better suited for frequent sealing of meats, bulk foods, or items you want to store long-term. If you’re using your sealer for heavy-duty chores or plan to seal many bags at once, look for models with higher vacuum strength.

Seal Bar LengthThis is the length of the area where the machine heats and seals the bag shut. It determines the maximum width of bag you can use. Shorter bar lengths (around 8-12 inches) are good for most home tasks like sealing single portions, while longer bars (over 15 inches) are better for larger cuts of meat, bulk foods, or when you need to seal multiple smaller bags at once. Choose a bar length that matches the size of the items you'll most often seal.

Duty CycleDuty cycle indicates how many times the vacuum sealer can work before needing a cool-down period. Some are ‘continuous duty’ and can operate nearly non-stop, which is necessary for commercial or very large batch tasks. Others need to rest after every few cycles, which is sufficient for occasional or weekly household use. If you plan to seal dozens of bags in a row, pick a sealer with a longer or continuous duty cycle to avoid downtime.

Bag CompatibilityThis refers to the types and thicknesses of bags the vacuum sealer can handle. Commercial-grade machines often work with thicker, textured, or specialty bags, which are more durable and better for preserving food over long periods. Consider if you want to use generic, brand-specific, or specially designed bags (like mylar or retort pouches). If you want flexibility in what bags you use, choose a model with broad bag compatibility.

Manual vs. Automatic OperationSome vacuum sealers require you to manually operate the sealing process—usually you control the vacuum time and trigger the seal at the right moment—while others are fully automatic, handling everything with one button press. Manual control gives you flexibility, which is helpful for delicate items or those with moisture, while automatic is quicker and easier for bulk sealing of standard foods. Think about whether you prefer greater control or maximum convenience when making your choice.

Build Quality and MaterialsHeavy-duty sealers should have sturdy construction, often with stainless steel housing and high-grade internal components. This helps the machine last longer, especially when used frequently or for large jobs. Plastic-bodied machines may be lighter but are less durable over time. If you expect to use your vacuum sealer often or in a demanding environment, select one with solid, heavy-duty materials.

Maintenance and CleanabilityBecause vacuum sealers can get food particles or liquids inside, it’s important that they’re easy to clean and maintain. Features like removable drip trays, accessible sealing bars, and simple exterior surfaces make a big difference. For frequent or messy use (such as sealing meats or liquids), pick a machine designed for easy cleaning and check if replacement parts are available.