We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best High Temperature Tapes

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best High Temperature Tapes

Choosing the right high-temperature tape can make a big difference when working on repairs, crafts, insulation, or any project where heat resistance is essential. The most important thing is to focus on what temperatures the tape needs to withstand, how long it needs to hold up, what surface it's used on, and whether you need added features like electrical insulation or chemical resistance. Knowing your work environment and expectations will help guide your choice.Temperature ResistanceTemperature resistance refers to the maximum heat the tape can handle before it loses its adhesive strength or breaks down. It's important because using tape beyond its rated temperature can cause it to fail, which may lead to safety hazards or damage to your project. Tapes are usually rated for ranges like 150°C (302°F), 260°C (500°F), or even higher. If you're wrapping pipes for insulation, sealing oven doors, or doing electrical work in high-heat environments, you need a tape that can comfortably exceed your maximum temperature. Estimate the highest temperature your project will see and pick a tape whose rating is well above that.

Adhesive TypeAdhesive type defines how the tape sticks under high temperatures and different environments. Common adhesives include silicone, acrylic, or rubber. Silicone adhesives are especially good at remaining sticky even when hot, while acrylics might handle moderate temperatures and stick well to metals and plastics. Rubber-based adhesives may not be as heat-resistant. Think about the conditions: if your tape will face both heat and possible moisture, silicone is often best; if you're sticking to clean, dry surfaces, acrylic may work. Consider what surfaces you'll be applying tape to and choose the adhesive that aligns with both temperature and surface type.

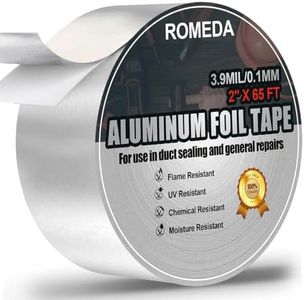

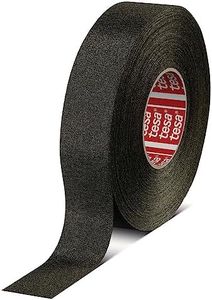

Backing MaterialThe backing material is what gives the tape its main structure and heat resistance. Materials like fiberglass, polyimide (often called Kapton), aluminum foil, and PTFE (Teflon) are typical. The choice impacts how flexible, strong, or heat-proof the tape is. For very high heat and electrical insulation, polyimide is popular. Fiberglass offers good strength and heat tolerance for things like wrapping pipes or wires. Aluminum foil reflects heat and is handy for shielding. Match your project needs—like flexibility, strength, or insulation—to the right backing material.

ThicknessTape thickness affects both durability and how well it conforms to uneven surfaces. Thicker tapes offer more protection and insulation but may be harder to wrap tightly or fit into small spaces. They can range from fractions of a millimeter to several millimeters thick. For detailed work where flexibility is key, thinner tape works better; for heavy-duty sealing and protection, thicker tape is preferred. Consider whether you need to wrap tight corners or cover broad surfaces, and choose a thickness that fits the job.

WidthWidth is how broad the tape is and determines how much area you can cover in one pass. Tapes come in narrow versions for precise, small repairs or wider rolls for bigger jobs. For wrapping skinny wires or intricate parts, a narrow tape (like ½ inch) is ideal. For large duct coverings or insulation, a wider tape minimizes overlaps and labor. Think about the size of the objects to be taped and select a width that matches the scale of your project.

Chemical and Electrical ResistanceChemical and electrical resistance are important if the tape will face chemicals, oils, or needs to prevent electrical shorts. Some tapes are specifically designed to resist solvents, acids, or provide high dielectric strength. If your work area is industrial or near electronics, make sure to check for these properties. For example, polyimide tapes are well-suited for electrical insulation. Consider your environment: if there’s any chance of chemical exposure or need for safety from electric current, select a tape with documented resistance.