We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Home Cnc Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Home Cnc Machine

Choosing a home CNC machine is an exciting process, as these machines allow you to shape and craft different materials right from your own workshop or garage. There are a lot of choices out there, and finding the best fit depends on what types of projects you have in mind, the materials you'll be working with, and the space available. Start by being clear about the kind of objects you want to create—whether woodworking, metal projects, or engraving—and think about how much space you have and how much time you're willing to spend learning new software or maintenance. Balancing your project goals with the machine's abilities will help you make a satisfying choice.Work Area (or Bed Size)The work area, sometimes called the bed size, describes the maximum length, width, and sometimes height of the material that the machine can handle. This is important because it limits the size of the pieces you can produce in one run. Smaller work areas are fine for craft projects, small signs, or jewelry, while larger work areas are needed for furniture pieces or bigger signs. Think about what the largest project you might want to make is, and try to choose a machine that can handle that size accordingly.

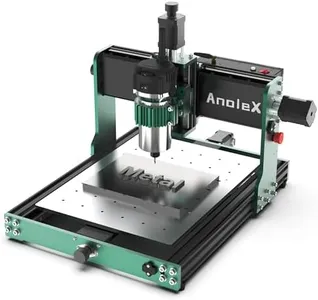

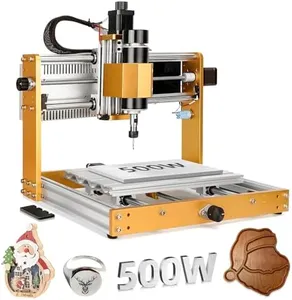

Material CompatibilityDifferent CNC machines are designed to work with different materials—some handle only wood or soft plastics, while others can also cut metals like aluminum. This matters because using the wrong machine for a tough material may damage both your project and the machine. If you intend to work with metals, make sure the machine is built for that. For mostly woodworking or plastics, most entry-level machines will suffice. Always match the machine to the type of materials you'll use most often.

Spindle Power (Motor Power)This refers to how powerful the cutting tool's motor is, usually measured in watts or horsepower. Higher spindle power means the machine can cut tougher materials faster and more efficiently, but it can also be noisier or require sturdier setup. For light tasks in soft materials, lower power is fine, while cutting denser woods and metals safely needs higher spindle power. Consider what materials you'll cut and how quickly you want your machine to work to decide the right level.

Precision and RepeatabilityPrecision means how accurately the machine follows the programmed path, while repeatability shows whether it can produce the same part again and again to the same standard. If your creations demand fine details or tight-fitting pieces, higher precision is essential. For more artistic or less exact projects, standard precision is usually sufficient. Look for machines that clearly state their accuracy numbers if precision matters to your projects.

Control Software and Ease of UseAll CNC machines run through software that translates your designs into instructions for the machine. Some come with beginner-friendly software, while others may require more technical expertise. If you're new to this, look for a machine with easy-to-learn, well-supported software. If you want more advanced control or custom projects, consider machines that support more powerful, open-source software. Your comfort level and willingness to learn new programs will help guide this choice.

Size and PortabilityThe physical dimensions and weight of the CNC machine will determine where you can put it and whether you need to move it around. Larger, heavier CNC machines offer bigger work areas and more stability, but they are not easy to relocate. Smaller, desktop versions can fit in compact workshops or even on sturdy tables. Make sure to measure your available space and think about whether you need to move the machine between uses.

Support and CommunitySupport refers to how easily you can get help, spare parts, or troubleshooting if you have problems with your CNC machine. Some brands have active online communities where users share tips and help each other, which can make a big difference when you’re starting out. If you're a beginner, or want to experiment and customize, choosing a machine with a strong user community and good manufacturer support is a smart move.