We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Hot Wire Foam Cutters

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Hot Wire Foam Cutters

Hot-wire foam cutters are specialized tools designed to slice through foam materials with precision using a heated wire. They’re excellent for hobbies, model-making, crafting, and some industrial uses. Choosing the right cutter means thinking about the types and sizes of foam you’ll work with, how often you’ll use the tool, and the level of detail and control you need. Knowing which features are important will help you find a cutter that’s safe, effective, and comfortable for your projects.Cutting Wire LengthThe cutting wire length determines how wide a piece of foam you can cut in one pass. Shorter wires (about 4-6 inches) are good for smaller projects and detailed work, giving you more control and stability. Longer wires (10 inches or more) are suitable for working with larger foam pieces, but may require more practice to achieve clean and straight cuts. Think about the kind of models, props, or objects you'll be making—if you mostly do small intricate cuts, go for a shorter length. If you deal with big sheets, a longer wire will be more versatile.

Temperature ControlTemperature control lets you adjust how hot the wire gets. Hotter wires cut faster and are best for thicker, denser foam, but can leave a rougher edge or cause more fumes. Lower temperatures are better for thin or delicate foam, where you want cleaner, more precise edges. Some cutters have fixed temperatures, while others offer variable settings. If you work with different foam types or need precise work, having adjustable temperature is a useful feature. If you consistently use similar materials, a fixed temperature may be simpler and sufficient.

Power SourceHot-wire foam cutters can be powered by mains electricity or batteries. Mains-powered units are reliable for long sessions and provide consistent heat but require access to a power outlet. Battery-powered cutters are portable and handy for working outdoors or in studios without outlets, though they may lack the power for thick materials or long jobs. If you mainly work at a fixed location, corded models are practical. If you need flexibility to move around or work in different places, consider battery options.

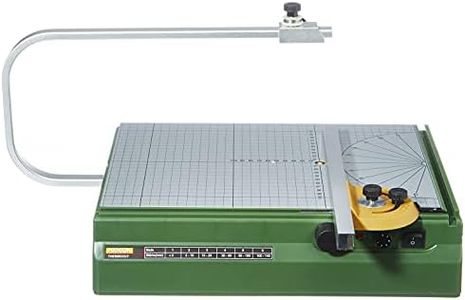

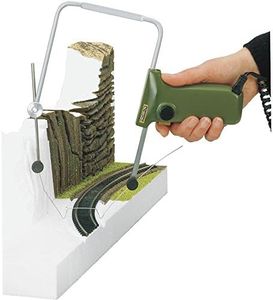

Frame Sturdiness and DesignThe frame holds the wire taut and shapes your cutting path. Sturdier frames provide steady, smooth cuts and last longer than flimsy ones. Lightweight plastic frames work for occasional light-duty use, while metal or reinforced frames are better for frequent or heavy work. Some frames are simple handheld pens for curves and freehand work, and others are tabletop models with guides for straight cuts. Your choice should depend on whether you value mobility and flexibility or precision and stability in your projects.

Safety FeaturesSafety features help prevent burns, accidental start-ups, and electrical hazards. Some cutters offer cool-touch handles, automatic shut-off, or shielded wires. For beginners, models with built-in safety precautions are reassuring and reduce the risk of accidents. Experienced users may manage with basic precautions, but it’s always wise to consider how safely you can use and store your cutter, especially if children or pets are around.

Ease of Wire ReplacementThe wire on a hot-wire foam cutter can wear out and will eventually break, so being able to replace it easily is important. Some models make wire changes simple with tool-free systems, while others require you to open up the frame and handle small parts. If you plan to use your cutter a lot, easy wire replacement will save you time and hassle.