We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

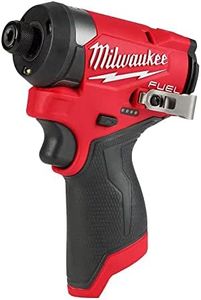

10 Best Impact Drivers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Impact Drivers

Choosing the right impact driver can make home improvement projects and repairs much easier, whether you’re a DIY enthusiast or working on more serious tasks. The most important thing is to match the tool to what jobs you expect to do. Think about the types of projects, how often you’ll be using the tool, and the kind of materials you’ll be working with. Understanding the main specifications will help you pick an impact driver that keeps up with your needs and feels comfortable to use.VoltageVoltage refers to the power output of the impact driver and is usually listed in volts (V). Higher voltage means more power, which can make the tool better at handling tougher jobs. Impact drivers commonly range from 12V to 20V. For lighter tasks like assembling furniture or driving screws into softwood, a lower voltage (around 12V) can be sufficient, making the tool lighter and easier to control. If you’re dealing with heavy-duty work such as driving large screws into dense materials, a higher voltage (18V or 20V) is best. Consider what tasks you’ll be doing most often—a compact, lighter tool for smaller jobs or a powerful tool for tougher applications.

TorqueTorque measures the turning force the impact driver can apply, usually noted in inch-pounds (in-lbs) or Newton-meters (Nm). Higher torque allows the driver to handle tougher fasteners and denser materials. Low torque (around 1,000 in-lbs) is suitable for lighter household tasks, while high torque (over 1,500 in-lbs) is ideal for demanding construction jobs or automotive work. For general use, a mid-range torque value balances power and control, while frequent heavy-duty use calls for a driver with high torque.

Speed (RPM and IPM)Speed in impact drivers is often given as RPM (rotations per minute) and IPM (impacts per minute). RPM tells you how fast the chuck spins; IPM shows how rapidly the driver delivers impacts. Higher speeds mean screws and bolts are driven faster, but too much speed can reduce control with small or delicate screws. For precise jobs, lower speeds prevent damage, while higher speeds and impact rates help for larger or stubborn fasteners. Many drivers let you adjust speed, making them useful for a variety of jobs.

Chuck/Collet SizeThis refers to the part of the impact driver that holds the bit, usually either 1/4-inch hex or less commonly, 3/8-inch. The 1/4-inch hex size is standard and works with most screwdriver and drill bits designed for drivers. It’s important because you’ll need to use compatible bits. If you already own certain bits, check that they fit the tool you want to buy. For most users, the 1/4-inch size keeps things simple and widely compatible.

Weight and ErgonomicsAn impact driver’s weight and how it feels in your hand matter a lot, especially if you’ll use it for long periods. Lighter models are easier for overhead or repetitive work and can reduce fatigue, but heavier models might feel more stable during tough jobs. Think about the tasks you usually do and how long you’ll hold the tool—lighter and more ergonomic drivers are good for everyday jobs, while slightly bulkier models could be preferable for occasional, intensive use.

Battery Type and RuntimeMost impact drivers are cordless and run on lithium-ion batteries. The battery’s amp-hour (Ah) rating indicates how long it will last between charges. A higher Ah means more runtime, which is useful for continuous or demanding projects. Lighter-use scenarios can get by with smaller batteries, keeping the tool more compact, while bigger batteries are best if you don’t want to stop and recharge often during a big task. Always make sure your battery is compatible with your other tools if you want a shared system.

Additional FeaturesModern impact drivers may include features such as LED lights, variable speed triggers, belt clips, or brushless motors. LED lights help illuminate workspaces, variable speed triggers give you better control for delicate tasks, and brushless motors increase efficiency and tool life. These features can make using the tool easier or more comfortable, so consider what would be most helpful in your projects and environments.