We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

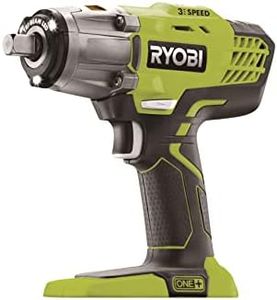

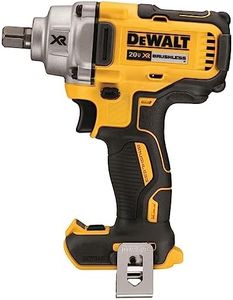

10 Best Impact Gun For Tires

From leading brands and best sellers available on the web.Recommended lists

Buying Guide for the Best Impact Gun For Tires

When looking for an impact gun (also known as an impact wrench) specifically for tires, it’s important to focus on features that ensure safe, quick, and easy removal and installation of lug nuts. The right choice will make tire changes efficient while protecting both your vehicle and tools from damage. Understanding the main characteristics of these tools helps you make an informed decision that matches your needs and typical usage.Power SourceImpact wrenches can be powered in several ways: air (pneumatic), battery (cordless), or corded electric. Air-powered models require an air compressor but often provide the most torque, which is favored in professional garages. Cordless (battery-powered) impact wrenches offer portability and convenience, making them popular for personal or roadside use. Corded versions are less common but provide consistent power without battery limits. When choosing a power source, consider how and where you will use the tool most often—if you need portability, cordless is likely best, while air-powered may suit frequent garage work.

Torque RatingTorque is a measure of the turning force the impact wrench can deliver and is stated in foot-pounds (ft-lbs) or Newton-meters (Nm). For tire work, enough torque is crucial to loosen and securely tighten lug nuts. Lower-torque tools (100-200 ft-lbs) might handle small cars, whereas mid-range (250-450 ft-lbs) suits most sedans and light trucks. Heavy vehicles or rusted nuts may need a wrench with 500 ft-lbs or more. Think about your vehicle type and typical needs: higher torque offers more versatility, but too much can risk overtightening or damage.

Drive SizeThe drive size refers to the square-shaped mounting point where sockets attach, with common sizes being 1/4", 3/8", 1/2", and 3/4". For tire-changing, 1/2-inch drive is the most standard as it matches typical lug nut socket sizes and balances strength with tool weight. Smaller drives may lack sufficient torque, while larger ones can be unnecessarily heavy unless you handle larger trucks or commercial vehicles.

Weight and ErgonomicsWeight affects how long and easily you can handle the tool, especially during repeated use. Lighter models are easier to maneuver for extended periods but may provide less power. Ergonomic handles, anti-vibration features, and comfortable grips reduce fatigue and increase safety. If you anticipate using the tool often or for long jobs, give preference to designs that fit comfortably in your hand and balance weight with performance.

Speed and Control FeaturesMany impact wrenches offer variable speed and multiple power settings. Variable speed enables you to start slow and avoid damaging the lug nut or wheel, while multiple speed modes let you adjust torque for loosening or tightening nuts as necessary. These features are important if you work on a variety of vehicles or want greater control to prevent over-torquing. Consider whether basic power is enough or if adjustable control will help you match different jobs.

Durability and Build QualityConstruction materials (such as metal versus plastic housing) and internal quality affect the lifespan and reliability of your impact wrench. Tools designed for professional use often incorporate rugged materials, reinforcing critical areas to handle regular, high-torque use. If you expect to use your gun frequently or in harsh conditions (like a workshop), prioritize durability and proven build quality—even for occasional home users, a well-built tool is a safer and more cost-effective investment over time.