We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best jointers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best jointers

Choosing a jointer can be an exciting step for anyone looking to improve their woodworking projects. A jointer helps you create flat surfaces on wood, making the pieces easier to join together for sturdy constructions and smooth finishes. Before picking a jointer, consider what kind of woodworking you do, the space available in your workshop, and the sizes of wood you usually work with. Understanding the key features will help you select a jointer that matches your needs and helps you achieve better results.Cutter Head WidthThe cutter head width tells you the maximum width of board that can be flattened or squared on the jointer. It's a critical feature because it determines the size of wood you can handle in one pass. Typically, jointers come in widths like 6 inches, 8 inches, 10 inches, and occasionally larger. Smaller cutter heads (like 6-inch) are great for hobbyists or those working on smaller projects. Medium widths (8-inch) suit most home workshops and can handle furniture-sized stock easily. Larger widths like 10-inch and above cater to serious woodworkers dealing with wide boards or larger volumes. Think about the common width of wood you use—choose a jointer size that matches or slightly exceeds your needs.

Bed LengthBed length refers to the length of the flat surface where the wood rests during jointing. This matters because a longer bed supports longer boards, ensuring more accuracy and stability. Shorter beds are suitable for smaller workpieces and fit better in compact workshops. Medium-length beds strike a balance between support and size, while longer beds are best for handling large or longer wood boards, providing the most accurate results. If your projects often include long lumber, a longer bed will make your work much easier, while shorter beds can suffice for smaller crafts or portable setups.

Cutter Head TypeThere are primarily two types of cutter heads: straight knife and helical/spiral cutter heads. Straight knife cutter heads use straight blades and are generally simpler and less expensive. They work well for basic flattening needs. Helical or spiral cutter heads use carbide inserts set at an angle in a spiral pattern, which makes for quieter operation, a smoother finish, and easier blade changes. They are also more forgiving when working with difficult or figured wood. If noise, finish quality, and easier maintenance matter to you, consider a spiral cutter head. If you do mostly straightforward work and want lower maintenance cost, a straight knife head could be sufficient.

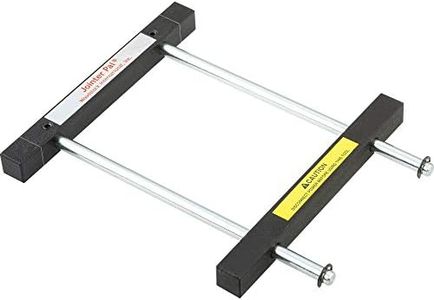

Fence AdjustabilityThe fence on a jointer acts as a guide for keeping the wood at a precise angle, most often 90 degrees. Fence adjustability allows you to tilt the fence for making beveled edges or working with various angles. Some jointers offer limited movement, while others have easily adjustable fences that can tilt to multiple angles. If you plan on making a variety of angled cuts or need high precision and versatility, a jointer with a highly adjustable and stable fence will suit you best. For users who only need right-angle cuts, basic fence adjustability will suffice.

Motor PowerMotor power, usually measured in horsepower (HP), determines how easily the jointer can handle tough or wide wood. Lower powered motors (around 1 HP) are suitable for light-duty or hobby work with softwoods and smaller boards. Mid-range motors (1–2 HP) can tackle most hardwoods and are nicely suited for typical furniture-making tasks. Higher powered jointers (over 2 HP) are built for demanding work, including heavy hardwoods and large volumes. Consider the type and size of wood you commonly work with—if you frequently joint thick or dense boards, more power will help prevent stalling and produce more consistent results.

Dust Collection CompatibilityJointers produce a lot of wood shavings and dust. Dust collection compatibility refers to how easily you can connect the jointer to a dust extraction system, which keeps your workspace cleaner and safer. Some jointers come with built-in dust ports of standard sizes, while others might have less efficient extraction setups. If you already have a dust collection system, make sure the jointer’s port matches. For organized shops or allergy-sensitive users, prioritizing good dust extraction compatibility will make your experience much more pleasant.