We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Label Makers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

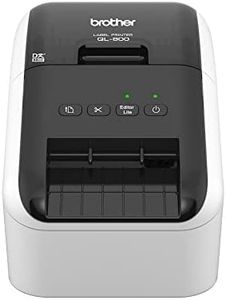

Buying Guide for the Best Label Makers

When choosing a label maker, it's important to think about how and where you plan to use it. Are you organizing things at home, labeling items for a small business, or handling more complicated projects in an office or warehouse? Consider where you'll use the labels, what you plan to label, and how often. Your needs will help you pick a label maker that feels easy to use and can keep up with your tasks. The right model should make labeling quicker and more effective, whether you're working with kitchen jars, storage boxes, cables, or files.Label Printing TechnologyLabel makers use different technologies, most commonly thermal printing or ink-based printing. Thermal label makers use heat to print onto special tape, which means you don’t need ink or toner. This makes them low-maintenance and great for everyday labeling jobs. Ink-based printers can produce more colorful, detailed labels but usually need cartridges or ribbons and are best for more professional or decorative needs. If you mostly want simple, long-lasting labels for home or office, thermal printing is a smart choice. If full color and complex graphics are important, then you might look at ink-based options.

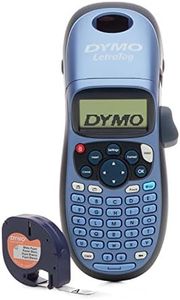

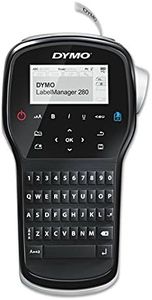

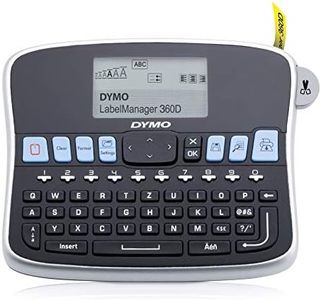

Keyboard and InterfaceThe keyboard and user interface are how you control the label maker and design your labels. Some machines have full QWERTY keyboards, while others have simple ABC layouts or use your phone via Bluetooth. If you'll be making lots of labels or want to type quickly, a QWERTY layout or PC connection is convenient. Simpler keypads or app-based designs are good for occasional use or if you prefer using a smartphone. Think about how comfortable you are with different interfaces and how often you'll make labels—frequent users benefit from a comfortable, efficient design.

Label Tape Size and TypeLabel tape comes in various widths, materials, and finishes, such as paper, plastic, fabric, or even stronger materials for outdoor use. The right size and type depend on what you're labeling and where it will go. Narrower tapes (6–12mm) are good for cables or small items, while wider tapes (18mm or more) suit large storage bins or clear signage. For labels exposed to water, sunlight, or heat, look for tapes that are laminated or weatherproof. Match the tape type and size to your labeling projects—more versatility is useful if your needs vary.

Power SourceLabel makers can be battery-powered, plug into the wall, or use rechargeable batteries. Portability is key here; if you need to label on the go or in different rooms, batteries or rechargeable models give you more freedom. If your label maker will sit on a desk, plugging in might be more convenient. Think about where and how long you'll be labeling at a stretch—pick a power source that matches your routine.

ConnectivityConnectivity refers to how you interact with the label maker beyond the built-in keyboard. Some models connect to a computer or smartphone so you can design labels with more fonts or images, or print batches efficiently. Bluetooth or wireless connectivity is handy for tech-savvy users who want more customization, while standalone models are straightforward and ready to go out of the box. If you anticipate complex labels or working with lots of designs, connectivity matters more.

Memory and Storage FeaturesSome label makers can save label templates or store frequently used text for quick reprinting. This is useful if you label the same things regularly or need to make a lot of labels at once. If your projects are repetitive, built-in memory will save time and effort. Occasional users or those making one-off labels may not need this feature, but it’s a big plus for higher-volume or business use.

Cutting MechanismAfter printing, labels are cut from the tape either manually or automatically. Automatic cutters are faster and can be more precise, which is a big help if you’re producing many labels in a session. Manual cutters require pressing a button or sliding a blade, suiting lighter jobs or infrequent use. If convenience and speed are priorities, especially in a work setting, automatic is best; for basic home labeling, manual is often sufficient.