We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

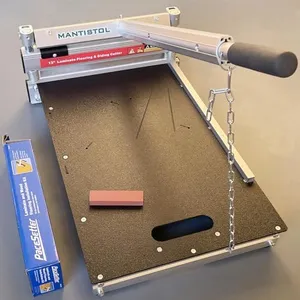

10 Best Laminate Flooring Cutter

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Laminate Flooring Cutter

Choosing the right laminate flooring cutter is important to make your floor installation smoother, safer, and more enjoyable. The right cutter ensures precise, clean cuts, reduces waste, and helps you work efficiently. Before buying, think about the type and thickness of flooring you'll cut, how often you'll use the tool, and the space you have for using and storing it. Understanding key specs will help you match your needs to the perfect product.Cutting Capacity (Width and Thickness)Cutting capacity tells you the maximum width and thickness of the laminate flooring planks the cutter can handle. This is important because not all cutters can cut every plank size. Cutters are usually divided into those that handle standard laminate (often up to 8-10 inches wide and 0.5 inches thick), and heavy-duty ones for wider or thicker planks (up to 13 inches wide or more, and 0.75 inches thick). Choose a cutter that comfortably fits your specific flooring; if you’ll work with thicker, wider planks or different flooring materials (like engineered wood or vinyl), opt for a cutter with a higher capacity.

Blade Material and SharpnessThe blade is what slices through your flooring, and its material and sharpness affect both cutting performance and the lifespan of the cutter. High-quality steel blades last longer and make smoother cuts, while cheaper blades might dull quickly or chip. In general, opt for a cutter with a hardened steel blade if you want durability and cleaner results, especially for larger projects. If you'll use it occasionally, standard steel blades are fine, but be prepared to sharpen or replace them over time.

Cutting Mechanism (Manual Lever or Guillotine)Flooring cutters mainly use either a manual lever or a guillotine-style mechanism. Lever-type cutters are easier to control and require less effort per cut, making them suitable for most DIYers and medium-sized jobs. Guillotine-style cutters provide extra force for thicker or more rigid materials but may require more strength to operate. Choose a lever mechanism if you value ease and comfort for regular laminate, but go for a guillotine style if you expect to handle tougher materials or thicker boards.

Weight and PortabilityDepending on where you plan to install your flooring, the weight and portability of your cutter can be a big factor. Heavier cutters may be more stable during use, but are harder to move between rooms or transport to different job sites. Lightweight and compact models are easier to carry, store, and use in tight spaces. If you’re working in one area and value stability, a heavier unit is fine, but if you expect to move the cutter around, choose a portable one.

Ease of Use and Safety FeaturesUsing a laminate flooring cutter should feel safe and simple, so look for features that make the process smoother. These might include ergonomic handles for comfortable gripping, a clear guide or measuring scale for accuracy, and safety guards to protect fingers. Some cutters may also have built-in clamps to hold material securely. If you’re new to flooring projects or value comfort, prioritize these user-friendly and safety-focused designs.