We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

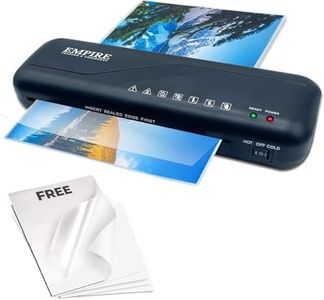

10 Best Laminating Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Laminating Machine

Choosing the right laminating machine can make your documents, photos, or creative projects look much more professional and last longer. To pick the best laminator for your needs, it's important to understand how these machines work and which features really matter to you. Consider what items you'll laminate—sizes, quantities, and how often you'll use the laminator. Think about whether you value speed, ease of use, or advanced features. With a little knowledge about the key specs, you can confidently choose a laminating machine that's a perfect fit for your needs.Pouch/Document Size CapacityThis spec refers to the maximum size of document or pouch that the laminator can handle. Most laminators are measured by the width they can accommodate, such as A4 (8.5 inches), A3 (12 inches), or even larger. If you typically laminate small items like photos or ID cards, a compact model may suffice. For larger offices or if you work with posters, presentations, or legal documents, look for machines with a wider capacity. Consider your most common project size, and make sure your chosen laminator can handle it comfortably.

Laminating Thickness (Micron/Mil Rating)This specification describes the thickness of laminating film the machine can process, usually given in microns (mic) or mil (1 mil = 25 microns). Thicker pouches (like 5 mil or above) offer more rigidity and protection than thinner ones (like 3 mil). If you need durable, firm results for items like ID badges or covers, choose a laminator that supports higher thickness. For everyday paper protection or temporary uses, a lower maximum thickness is enough. Always check that the machine matches the pouch thickness you'll use most often.

Laminating SpeedLaminating speed indicates how quickly the machine can laminate, typically measured in inches or millimeters per minute. For occasional or home users, speed isn’t crucial, as a slower machine may suffice. If you’re laminating large volumes regularly, such as in an office or school, a faster machine will save considerable time and reduce bottlenecks. Match the speed to your workload: infrequent use means speed is less of a concern, while frequent, high-volume use should push you toward faster options.

Warm-Up TimeWarm-up time is how long the laminator takes to reach the right temperature after being switched on. Some modern machines heat up in as little as one minute, while others may take five minutes or longer. Shorter warm-up times are convenient for busy settings or on-the-spot laminating. If you don’t mind waiting or plan to do all your laminating at once, a longer warm-up time may not matter. Consider your patience and workflow to determine how much importance this has for you.

Jam Release FeatureA jam release or anti-jam feature allows you to easily clear misfeeds or jams, which can happen if items are not fed straight or pouches are loaded incorrectly. For beginners or anyone worried about ruining documents, having a manual or automatic jam release provides peace of mind and reduces frustration. If you’ll be using the laminator with lots of different users or in a fast-paced environment, this feature becomes particularly useful.

Hot vs. Cold Laminating CapabilitySome laminators can handle both hot and cold laminating, while others only do one type. Hot laminating uses heat to seal the pouch, suitable for most documents. Cold laminating uses pressure-sensitive adhesive, ideal for heat-sensitive items like photos or certain inks. If you plan to laminate a variety of items, especially delicate ones, look for dual capability. If your needs are straightforward, a hot-only or cold-only model may do the job.