We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

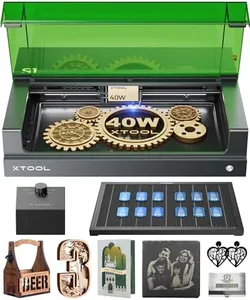

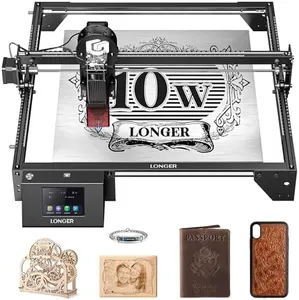

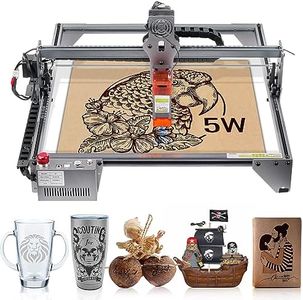

10 Best Laser Cutter

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Laser Cutter

Choosing a laser cutter involves understanding your needs for cutting, engraving, and the types of materials you'll work with. The right model will depend on how detailed your projects are, the workspace you have available, and your experience level. Consider the size of the items you plan to create, how much precision is necessary, and any safety or maintenance requirements. Knowing your key requirements will help you find a laser cutter that fits your workflow without overwhelming you or limiting your future creativity.Laser Power (Wattage)Laser power, measured in watts, determines how deep and fast the machine can cut through different materials. Lower wattage lasers, typically below 40W, suit engraving or cutting thin materials like paper and some plastics. Mid-range (40W to 80W) provide a balance, capable of cutting thicker woods or acrylics while still handling detailed engraving. High wattage (above 80W) handle dense materials like metal or thick hardwood quickly, though they require more safety precautions and often more space. Assess the types and thicknesses of materials you plan to work with regularly—if you're focusing on craft projects or small items, lower wattages generally suffice, while robust fabrication needs point towards higher wattages.

Work Area Size (Bed Size)The bed size is the maximum area your laser cutter can work on in a single session. Smaller beds (around 8x12 inches) are suitable for jewelry, small crafts, or hobbyist work. Medium sizes (12x20 inches up to 18x24 inches) accommodate most home projects, signs, and prototypes. Large beds are essential for industrial tasks, furniture parts, or larger signage, often taking up significant workspace. Choose a bed size based on the largest piece you intend to cut or engrave; having more space than needed can add to the machine’s cost and required workspace, while too small a bed can be restrictive and require splitting projects into multiple parts.

Supported MaterialsDifferent laser cutters are designed for specific materials—some excel at wood, acrylic, and leather, while others handle glass, fabric, or even metals. CO2 lasers are common for non-metal materials, while fiber lasers handle metals. It's important to check what materials a machine can process and to ensure it matches your intended projects. Make a list of materials you want to experiment with; select a cutter that specifically lists compatibility with those materials to avoid frustration or damage.

Precision and ResolutionPrecision, sometimes called resolution, describes how accurately the laser can follow design details and how crisp edges and engravings will be. Measured in dots per inch (DPI) or as minimum feature size, higher numbers mean finer detail. Low-precision machines may struggle with tiny text or detailed graphics, while high-precision models faithfully reproduce intricate designs at small scales. If your work requires a lot of fine details (like engraving graphics or creating inlays), prioritize higher precision, but for simple cuts or basic shapes, entry-level accuracy often suffices.

Cooling SystemLasers generate heat, so efficient cooling systems keep the machine running safely and protect its lifespan. Air-cooled systems are simple and common in smaller, lower-powered units and require little maintenance. Water-cooled systems, usually found in higher-powered or professional units, handle more heat but require you to maintain the coolant level. If you’ll be running the machine for long periods or using a high-powered model, reliable cooling is crucial. Casual users with short sessions can generally rely on simpler systems.

Safety FeaturesLaser cutters use intense beams that can be hazardous without the right safeguards. Look for features like safety interlocks that shut the laser off when the lid is open, enclosed designs, emergency stop buttons, and proper ventilation for fumes. These features protect both you and others around you. If you’re new to laser cutting or plan to use the machine in shared or home spaces, prioritize these protections for peace of mind and regulatory compliance.

Software CompatibilityEvery laser cutter relies on software to create or import designs, set parameters, and operate the machine. Some only support proprietary software, while others accept standard formats (like SVG, PDF, DXF) and integrate with popular design programs. Easy-to-use software is important for beginners, while advanced users may want more customization or integration options. Know whether you need beginner-friendly software or if you require compatibility with programs or file formats you already use.

Maintenance RequirementsKeeping a laser cutter operating smoothly requires some upkeep, such as cleaning lenses, checking alignment, and occasionally replacing consumables like cooling fluids or exhaust filters. Some machines simplify these tasks, while others need more hands-on attention. If you want a low-hassle experience, choose a model known for easy maintenance, but if you enjoy tinkering and don’t mind the extra effort, you can expand your options.