We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Laser Engravers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Laser Engravers

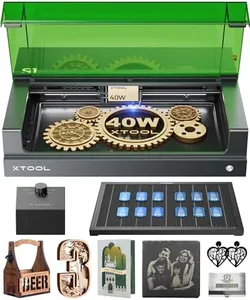

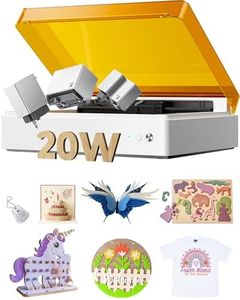

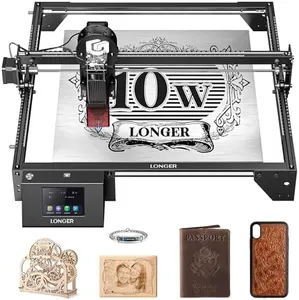

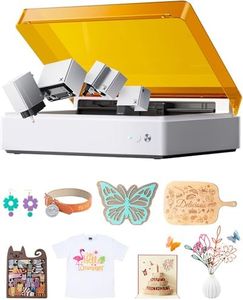

Choosing a laser engraver can feel overwhelming given the variety of machines available, but focusing on your intended use and understanding key features will help you make the right choice. The most important step is to clarify what you plan to engrave—materials, project size, and how often you’ll use the machine. By breaking down the main specifications and how they relate to your needs, you'll be able to prioritize what’s important to you and avoid being distracted by unnecessary features.Laser PowerLaser power, usually measured in watts, refers to the strength or intensity of the laser beam. It's important because it determines what materials you can cut or engrave and how quickly the machine can work. Lower power (like 5-10W) is suitable for engraving or marking softer items like wood, leather, and certain plastics, but won't cut through thick materials. Mid-range power (around 20-40W) allows you to engrave on a wider range of materials, including some metals, and cut through thicker woods or acrylics. High power (50W and above) is best for industrial needs, cutting through dense or thick materials and engraving metal more efficiently. Think about the hardest material you want to engrave or cut; let that guide the minimum power you need to achieve your projects.

Engraving AreaThe engraving area is the maximum surface size the machine can handle in one session. It's important because it limits the size of items you can engrave without repositioning them. Small engraving areas (like 100x100mm) are good for personalized items such as jewelry, tags, and small crafts. Medium areas (around 300x400mm) support items like phone cases, plaques, or small signs. Large areas (over 400x600mm) are best for signage, large artworks, or multiple products at once. Consider the largest item you want to work with—your engraving area should meet or exceed that size to ensure smooth workflow.

Supported MaterialsThis spec tells you what kind of materials the laser engraver can handle and is crucial because not every machine works with every material. Some lasers work only with soft materials like wood and acrylic, while others can handle harder items like glass, certain metals, or stone. If you want to personalize metal items or do fine glass etching, look for a model that can support those tasks. Check the types of projects you want to do, then confirm whether your chosen machine can accommodate your material list.

Laser TypeLaser engravers use different laser types, usually CO2, diode, or fiber lasers. The type affects what materials you can engrave and how detailed the results are. CO2 lasers are common for non-metal substances like wood, plastic, leather, and glass, offering good speed and versatility. Diode lasers are smaller and more affordable but less powerful, ideal for hobby work on soft materials. Fiber lasers excel at marking and engraving metals and are more common for professional and industrial purposes. Think about the material versatility and detail you require—choose the laser type that aligns with your most common project needs.

Software CompatibilitySoftware compatibility refers to the design programs and control software you can use with your engraver. The right software makes designing and sending your projects to the machine much easier and can expand your creative possibilities. Some engravers use proprietary software, while others work with popular design programs or accept standard file formats like SVG or DXF. If you already use certain graphic software, make sure your engraver supports it, or check that you’re comfortable learning something new. This is especially crucial if you want to import custom designs or need compatibility for batch processing.

Safety FeaturesLaser engravers can be dangerous, so safety features are important for both home and professional use. Common safeguards include protective shields around the laser, emergency stop buttons, auto-off when the lid is opened, and proper ventilation systems. Simple engravers may have minimal safety features, while more advanced or enclosed models provide better protection. If you’ll be working in a shared or family space, look for machines with extra safety built in to minimize risks.

Ease of UseEase of use encompasses aspects like how easy it is to set up the machine, calibrate the laser, load materials, and operate the control panel or software. A user-friendly machine is especially important for beginners or hobbyists. Look for clear instructions, touchscreens, automatic focusing, and guided setup features. If you want a plug-and-play experience, consider models that are known for straightforward operation, rather than those requiring detailed manual calibration.