We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Lathe Chuck For Bowls

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Lathe Chuck For Bowls

Choosing the right lathe chuck for bowl turning can make your woodworking projects safer, simpler, and more enjoyable. The chuck is a clamp that holds your workpiece (the wood you’re turning into a bowl) securely on the lathe, so you want to match your choice to your lathe, your project size, and your own experience level. Key specifications to compare often include size, jaw type, mounting thread size, gripping mechanism, and material quality. Understanding how these factors relate to your turning needs will help you choose the right chuck to ensure reliable grip, easy operation, and compatibility with your lathe.Chuck SizeChuck size refers to the diameter and jaw capacity of the chuck, determining the range of bowl sizes it can securely hold. A smaller chuck is typically suitable for turning smaller bowls or pieces, while a larger chuck can handle bigger, heavier workpieces. Small (around 3-inch diameter) chucks are best for light, more detailed projects or small lathes; mid-size (3 to 4 inches) cover most general bowl turning needs; large chucks (over 4 inches) are designed for heavy and big projects. Consider the sizes of bowls you plan to turn and make sure the chuck matches the majority of your work.

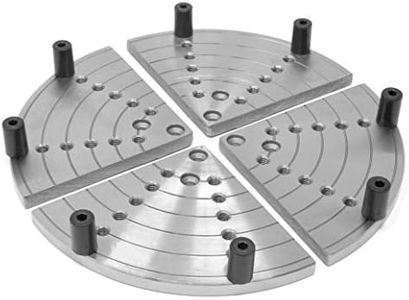

Jaw TypeJaw type refers to the style and shape of the jaws that grip the wood. There are dovetail jaws, serrated jaws, and flat jaws, each providing different levels of grip. Dovetail jaws are commonly used for bowl turning because they hold well in a dovetail recess or tenon on your wood blank. Serrated jaws provide extra security for irregular shapes. If you plan on turning mostly bowls, dovetail jaws are a good all-purpose choice; however, if you want to turn a variety of objects, consider a chuck that offers interchangeable jaws.

Mounting Thread SizeThe mounting thread size is the dimension of the screw threads that attach the chuck to your lathe’s spindle. Common thread sizes are based on the lathe model and region (for example, 1" x 8 TPI or M33 x 3.5mm). Having the correct thread size is crucial for safety and function—an incompatible chuck simply won’t fit your lathe. Check your lathe’s specifications and make sure your chuck matches, or look for models with adapters if you have more than one lathe or anticipate upgrading.

Gripping MechanismThe gripping mechanism is how the jaws are tightened or loosened, often using either a key (lever or T-bar) or a scroll (scroll chucks). Keyed chucks allow for quick, strong adjustments, while scroll chucks offer smooth, even tightening and easy one-handed operation. For bowl turning, scroll chucks are popular due to their speed and reliability, but for heavy-duty or repetitive tasks, a lever-action system can be faster. Choose a gripping style that you feel is safe and comfortable for your hands and workflow.

Material Quality and ConstructionChucks are made from various grades of steel and often finished or coated for rust resistance. Premium quality ensures longevity, better accuracy, and stronger grip. Heavier, all-steel chucks usually last longer and hold better on larger pieces. If you turn bowls frequently or work with harder woods, investing in a better-built chuck makes sense; for occasional use with soft woods, a lighter or simpler model may suffice.