We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

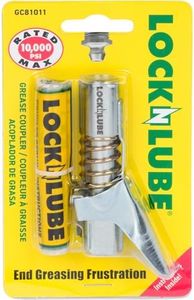

10 Best Locking Grease Coupler

From leading brands and best sellers available on the web.Buying Guide for the Best Locking Grease Coupler

Choosing a locking grease coupler may seem straightforward, but paying attention to a few important features ensures you get one that’s easy to use, reliable, and suitable for your greasing tasks. A good coupler will help you make secure connections with grease fittings, prevent leaks, save time during maintenance, and minimize frustration in the workshop or garage. When comparing your options, focus on a balance of durability, ease of connection and release, pressure rating, and compatibility with your grease gun and fittings.Locking MechanismThe locking mechanism determines how securely the coupler attaches and detaches to the grease fitting. A strong, user-friendly locking mechanism makes it easy for you to connect and disconnect the coupler with one hand, reducing the frustration of leaks or the coupler popping off under pressure. Simpler push or lever-actuated locks are ideal for quick jobs and frequent disconnects, while more robust mechanisms may take an extra step but offer better holding power. Choose a mechanism that feels comfortable and secure based on how often you’ll use it and the types of equipment you’re servicing.

Pressure RatingPressure rating tells you the maximum pressure the coupler can handle before failing or leaking. Common grease guns can generate varying levels of pressure, usually between 3,000 and 10,000 PSI (pounds per square inch), while some heavy-duty use may require even more. Lower pressure ratings are fine for small home maintenance or hobby use, but for automotive, agricultural, or industrial jobs, higher ratings ensure safety and reliability. Match the pressure rating to your greasing tool and the demands of your work environment.

Jaw Quality and CountThe jaws are the internal parts of the coupler that grip the grease fitting. More jaws (typically three or four) offer a firmer, more even grip, which is important for preventing leaks and keeping the coupler in place under pressure. Higher jaw count and better quality materials in the jaws mean the coupler will last longer and perform better, especially if you’ll be greasing frequently or working at awkward angles. For occasional use or light jobs, basic jaws might suffice, while frequent or heavy users should seek higher jaw quality and count.

CompatibilityCompatibility refers to whether the coupler fits your grease gun and the most common zerk (grease) fittings you encounter. Most couplers are designed for standard fittings, but certain equipment may use specialized sizing. Always check the thread type and diameter before buying to ensure a secure and leak-free connection. If you maintain a variety of machines or vehicles, opt for a more versatile coupler that fits a wider range of fitting sizes.

Ease of UseThis covers features like ergonomic grips, single-handed operation, or mechanisms that allow quick release. If you often work in tight spaces or need to grease many fittings at once, an easy-to-use coupler saves time and effort. Consider how much strength is needed to attach or detach the coupler, and whether it’s comfortable to use repeatedly. Pick the level of convenience that matches how intensively and frequently you plan to use the coupler.

Build Material and DurabilityDurability depends on the material construction of the coupler—common choices being hardened steel or zinc-coated parts. Durable build quality means the coupler will resist wear, corrosion, and accidental drops, giving you better long-term value. If you’ll use the tool in harsh environments or need it to last for years, solid construction is very important. For occasional use, lighter materials may be acceptable.