We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

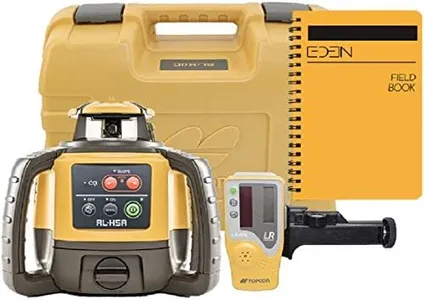

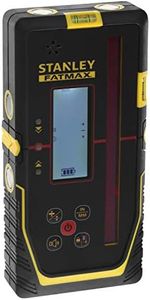

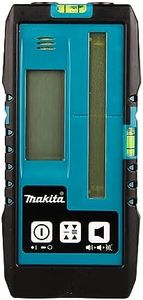

10 Best Machine Mounted Laser Receiver

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Machine Mounted Laser Receiver

Choosing a machine-mounted laser receiver can greatly improve the accuracy and efficiency of earthmoving, grading, or construction equipment. It's important to understand how these receivers work and which features will support your specific needs on the job site. To find the best fit, consider the environment you'll be working in, the types of machines you'll be using, and how you plan to integrate the receiver with your workflows.Detection RangeDetection range is the maximum distance at which the laser receiver can reliably pick up a signal from the rotating laser. This determines how far your machine can work from the laser transmitter while still receiving guidance. Detection ranges are often split into short-range (up to about 300 meters), standard-range (300-500 meters), and long-range (over 500 meters). If you frequently work on large sites, a longer detection range lets you cover more area without moving the transmitter, whereas smaller projects may work perfectly well with a standard or short-range system.

Display TypeThe display type describes how information from the laser receiver is communicated to the machine operator. Some receivers use simple LED displays right on the receiver, while others connect to in-cab control boxes with graphical or numeric displays. Simple LED displays are fast and easy for rough grading, but for detailed work or in-cab use, a more advanced visual display might improve precision and comfort. The right choice depends on the type of work and operator preferences.

Mounting OptionsMounting options indicate how the receiver attaches to your equipment. Common systems include magnetic mounts, clamp mounts, or brackets designed for specific machines. This affects how easily you can move the receiver between machines and how securely it stays in place during operation. Choose a mounting system that is compatible with your equipment and suits your need for either flexibility (for frequent moves) or secure, fixed installation (for dedicated machines).

Accuracy and ResolutionAccuracy and resolution refer to how precisely the receiver can detect changes in the laser beam's level and how closely it interprets the grade information. High-accuracy receivers provide more detailed feedback, which is important for fine grading or projects where precise elevations are critical. For rough grading, lower accuracy might be sufficient, but for finish work or when integrating with automated machine control, higher resolution can make a big difference.

Power Supply and Battery LifePower supply and battery life describe how the receiver is powered and how long it operates between charges or battery changes. Receivers may run on replaceable batteries, rechargeable batteries, or even draw power from the machine. If your projects involve long workdays or remote locations, longer battery life or easy swap batteries will keep you productive with less downtime. Assess how often you're able to change or recharge batteries to pick the best option for your workflow.

Machine CompatibilityMachine compatibility means whether the receiver can be connected and used with your specific type and model of equipment. Some receivers are universal, fitting many different machine types, while others work best with certain brands or models. Make sure the receiver's size, attachments, and interfaces match your machines—this ensures reliable performance and smooth installation.

Durability and Weather ResistanceDurability and weather resistance indicate how well the receiver can withstand tough job site conditions like rain, dust, vibrations, or impacts. Units with higher ruggedness ratings or standards (like IP67) are better suited for outdoor or harsh environments. If you work in variable weather, choose a robust receiver to avoid downtime and maintain accuracy all season long.