We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Making Candle Wicks

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Making Candle Wicks

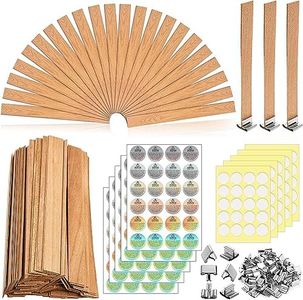

Choosing the right materials and products for making candle wicks is key to successful candle crafting. The wick plays a central role in how cleanly and efficiently a candle burns, influencing aspects like burn time, flame size, and scent throw. When selecting wick components or ready-made wicks, it's important to match them to the type of candle you plan to make, considering factors like wax type, candle size, and any added fragrances or colorants. Proper wick selection creates a safer, brighter, and more enjoyable candle experience.Wick MaterialWick material refers to what the wick is made from, which impacts burn behavior and compatibility with different waxes. Common materials include cotton, wood, hemp, and sometimes paper cores. Cotton is most popular due to its clean and reliable burn, while wood produces a crackling sound and a unique aesthetic. Choosing the right material is important because some burn hotter or slower than others, affecting both safety and performance. If you are making container candles or votives, cotton is a safe bet, but for novelty or decorative candles, you might opt for wood or other materials for special effects. Your candle's form and intended use should guide your choice of wick material.

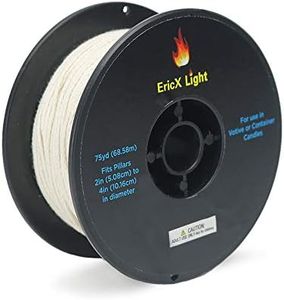

Wick Size (Thickness and Ply)The wick size relates to its thickness and the number of fibers (ply or braid), directly affecting the flame size and how much wax is drawn up. A too-small wick may drown in melted wax and fail to burn properly, while a too-large wick creates a big flame that can be hazardous. Typically, thin wicks suit thin tapers and small candles, while thicker or multi-ply wicks are designed for larger, wider candles. To pick the right size, match the wick diameter to your candle diameter—larger candles need bigger wicks to ensure an even burn across the surface.

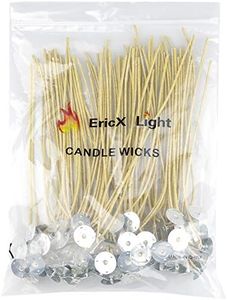

Wick Coating or TreatmentSome wicks are pre-waxed or treated with substances to make lighting easier and burning more stable. Waxed wicks are stiffer, making them easier to place in molds, and help start the burning process. Others might be chemically treated to enhance performance with certain waxes. The importance of this spec comes down to how you make your candles: hand-dipping often requires non-coated wicks, while poured candles can benefit from pre-waxed options. If convenience and ease of use are priorities, look for pre-waxed or treated wicks.

Type of Candle SupportedWicks are often designed for specific candle types, such as container candles, pillars, tea lights, tapers, or votives. This is important because the required wick characteristics (burn rate, rigidity, etc.) differ for each type. For example, container candles may use a softer braid that curls into itself, while pillars use a more rigid wick. To navigate this, always check recommended use indicated on wick packaging or description, and match your wick selection to the kind of candle you’re making.

Burn CharacteristicsBurn characteristics refer to how the wick influences aspects like sooting, mushrooming (carbon buildup), flame stability, and scent throw. A good wick will provide a stable, consistent flame, minimal smoke, and an even melt pool. Poor burn behavior can result in odors, uneven burning, or excessive soot. To pick the right wick, consider the ingredients in your candle (natural vs. synthetic wax, heavy fragrance use, etc.) and look for wicks known for clean burning. If you're unsure, it's smart to make small test candles before committing to a large batch.