We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Meat Band Saw

From leading brands and best sellers available on the web.Buying Guide for the Best Meat Band Saw

Choosing the right meat band saw is all about understanding your specific needs and the typical tasks you'll use it for. Whether you're a home user, a small business owner, or working in a professional setting, the best meat band saw for you should match how much meat you plan to process, your available space, and your comfort with different features and safety mechanisms. Knowing the main specifications helps you make a confident choice and avoid common frustrations.Motor PowerMotor power indicates how strong and efficient the saw is at cutting through meat and bone. This is usually measured in horsepower (HP) or watts. If you only handle small amounts of soft meat or occasional use, a lower-powered motor will likely be enough and may run more quietly. Medium-powered motors are good for regular use and can handle moderate bone and tougher cuts. High-powered motors are designed for frequent, heavy-duty use and dense bones, making them ideal for butchers or commercial settings. Think about the toughest material you plan to cut—choose a motor that handles your needs without straining.

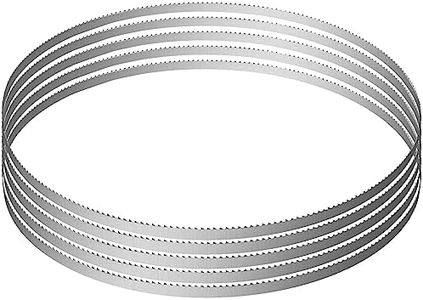

Blade Size and TypeBlade size, typically given as length in inches, and the blade type (tooth design and width) determine what you can cut and how cleanly it slices through different cuts of meat and bone. Shorter, finer blades excel for delicate work and soft meats, while longer, wider blades with coarse teeth are more suited for larger cuts and bone. The right blade for you depends on whether you mostly process boneless meat or tougher, bone-in pieces. Pick a blade size that matches your most common tasks—the right choice gives you cleaner cuts and less waste.

Cutting CapacityCutting capacity refers to the maximum height and width of meat (sometimes called throat capacity) that the band saw can handle at once. If you process large slabs, thick roasts, or whole sides of meat, a larger capacity is necessary. Smaller capacities are easier to handle but may limit what you can saw. Your typical meat size should guide this choice—don't go too small if you'll work with larger pieces, but you also don't need a larger capacity if you'll only saw smaller cuts.

Construction MaterialThe build material of the band saw affects its durability, ease of cleaning, and longevity. Stainless steel is the most common choice for professional and home-grade saws because it resists rust and is food-safe. Some entry-level or light-use models might use aluminum or coated metals, which are lighter but might wear out faster. If hygiene and long-term use matter highly to you, or if you want low-maintenance equipment, go for stainless steel. For lighter, occasional use, less expensive materials can suffice.

Safety FeaturesSafety features prevent accidents and make operation safer, especially important in fast-paced or novice environments. Common safety elements include blade guards, safety switches, non-slip feet, and emergency stop buttons. Safer designs might also include automatic shutoff or guards that cover more of the blade. If you're new to using power saws, or will have multiple users (such as in a business), prioritize safety features. Even experienced users should not overlook safety; it's vital for long-term, worry-free use.

Ease of CleaningMeat band saws need to be cleaned thoroughly after each use due to health and hygiene rules around raw meat. Some saws are designed to come apart easily, with fewer crevices for debris and removable parts that are dishwasher-safe. Others may have more permanent construction that takes longer to clean. If you're processing meat regularly or in larger quantities, easy cleaning can save you time and ensure you meet safety standards.