We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Metal Chop Saws

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Metal Chop Saws

Choosing a metal chop saw involves thinking about the type and amount of metalwork you plan to do. The right saw not only cuts accurately but should also be comfortable and safe to use. Before you make your choice, consider where and how often you’ll use it, the types of metals you’ll work with, and the precision you require. Knowing these details will help you match your needs to the saw’s features, leading to better results and a smoother experience.Blade SizeBlade size describes the diameter of the saw’s cutting disc or blade. It directly affects how thick and wide a piece of material you can cut in a single pass. Common sizes include 10-inch and 14-inch. Smaller blades are lighter and easier to handle, but limit the size of metal they can cut, making them a good fit for hobbyists or small DIY tasks. Larger blades are best for those working with bigger or thicker metal, such as pipes and thick bars, making them suitable for more serious or frequent use. Think about the largest size you may need to cut in your projects and choose a blade size that covers that need.

Motor PowerMotor power is usually measured in amps or horsepower and indicates how easily the saw can cut through tough materials without slowing down or bogging out. Lower powered saws (under 15 amps or 2 horsepower) can handle thin or soft metals, while higher powered saws are better for cutting thick or hardened metals. If you’ll mainly work with light metal or only use the saw occasionally, a lower-powered saw is likely enough. If you expect to cut heavy-duty material often or function in a workshop, a more powerful motor provides consistent performance.

Cutting CapacityCutting capacity describes the maximum width and thickness of metal the saw can handle in a single cut. This spec depends on both the blade size and the design of the saw, including how far the arm can move. If you mainly cut small pipes, rods, or bars, most standard chop saws will work. For larger profiles or thick industrial materials, ensure the cutting capacity matches your largest project needs, otherwise, you may find yourself limited down the road.

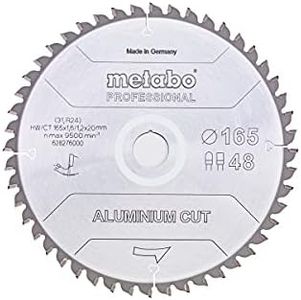

Type of BladeMetal chop saws use either abrasive wheels or carbide-tipped blades. Abrasive wheels grind through metal and are cheaper, but wear out quicker and produce more sparks and heat. Carbide-tipped blades cut cleaner, faster, and last longer, but are more expensive upfront. If you value cleaner cuts with less finishing, or plan to cut a lot, a carbide-tipped blade may be better. For occasional and basic jobs, abrasive wheels are usually sufficient.

Base and Vise QualityThe base and vise hold your metal in place during cutting. A strong, stable base made of steel or cast iron resists vibration and helps ensure straight cuts. The vise should securely clamp various shapes and sizes of material. If stability and precise cuts are important for your projects, focus on saws with a solid, heavy base and a robust, adjustable vise. For lighter, quick tasks, a simple base may be enough.

Spark and Debris ManagementCutting metal produces sparks and small metal fragments. Some saws are designed to direct these away from the user and may include spark guards or debris collectors. Good spark management adds safety and makes cleanup easier. If you work indoors or in a shared space, or want to improve safety and cleanliness, look for saws with effective spark and debris control features.

PortabilityPortability refers to how easy it is to move the saw around. If you need to work in different locations or have limited storage space, choosing a lighter saw or one with a carry handle is helpful. For a dedicated workshop with a stable workbench, portability may not be a big concern. Match your choice to how and where you’ll use the saw most often.