We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Metal Ramp For Shed

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Metal Ramp For Shed

Choosing a metal ramp for a shed may seem straightforward, but the right ramp will make access safer, easier, and more convenient for moving lawn mowers, wheelbarrows, heavy equipment, or even bikes in and out. The right fit depends on understanding the ramp's key characteristics and matching them to your needs. Think about what you’ll be moving, how often, and the shed’s entry height and width. It's also important to consider the terrain around your shed and whether you'll need a temporary or permanent solution. With a clear idea of how you'll use the ramp, you can select a model that balances safety, durability, and ease of use.Weight CapacityWeight capacity refers to the maximum load the ramp can safely support, including the weight of whatever you’re moving plus yourself if you’ll be walking or riding up the ramp. This is crucial because a ramp that's too weak can be dangerous or get damaged quickly. Lower capacity ramps are suitable for lighter loads such as bikes or empty wheelbarrows, typically around 500 pounds. Medium capacities handle garden machinery and small mowers, ranging up to 1000 pounds. Heavy-duty ramps intended for ride-on mowers or small vehicles may support 1500 pounds or more. Always overestimate the total weight you’ll move to ensure safety and longevity.

Ramp LengthRamp length determines the angle or steepness of the ramp when in place. A longer ramp creates a gentler incline, making it easier and safer to push or drive equipment up or down. The right length depends on the height you need to bridge, which is the distance from the ground to your shed floor. Shorter ramps (3-4 feet) are best for sheds with low entryways (less than 8 inches high), but become very steep with higher thresholds. Medium ramps (5-7 feet) are good for typical garden sheds with higher entries, while longer ramps (8 feet or more) are suited for higher or less accessible sheds. Always choose the longest ramp your space allows to keep the gradient manageable.

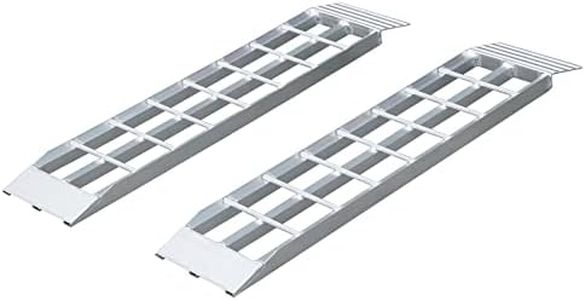

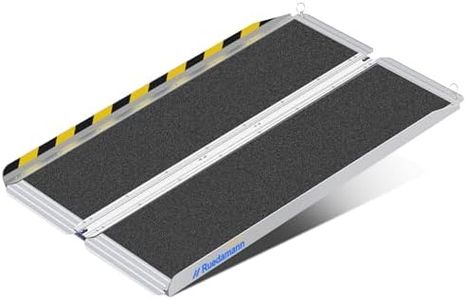

Ramp WidthRamp width measures the usable surface across the ramp. This is key to stability and compatibility with what you’ll be rolling up and down. Narrower ramps (around 24 inches) suit single tracks like bicycles or narrow wheelbarrows, but may not fit wider equipment. Medium widths (30-36 inches) accommodate most walk-behind mowers and garden carts comfortably. Extra-wide ramps (40 inches or more) are intended for riding mowers or for people who want more generous space for safety. Check the width of your largest equipment to make sure it will fit easily, and give yourself a little extra room for maneuvering.

Surface TextureThe surface texture affects how much grip you have when using the ramp, both for wheels and feet. Smooth surfaces are easier to clean, but can become slippery, especially in wet weather. Most shed ramps have a textured, ribbed, or perforated surface to improve traction and reduce slipping. For safety, especially in wet or muddy conditions, look for a surface with aggressive grip features. If the ramp will be used primarily for walking or pushing heavy items by hand, this becomes even more important.

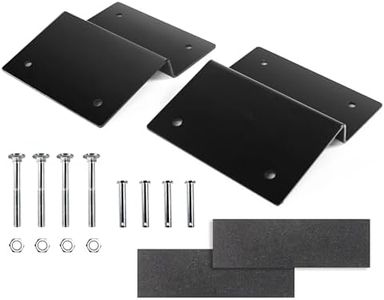

Portability and InstallationThis describes how easy it is to move, install, or remove the ramp. Some ramps are designed to be permanently fixed to the shed, making them more stable and secure but difficult to move. Others are lightweight or have carrying handles, meant for temporary or seasonal use. Fixed ramps suit users who want simple, everyday access, while portable ones are better if you need to store the ramp away when not needed or use it in multiple locations. Consider how often you’ll need to move the ramp and whether you prefer a permanent or flexible setup.

Rust ResistanceRust resistance refers to the ramp’s ability to withstand exposure to moisture without corroding. Since most shed ramps live outdoors year-round, exposure to rain, dew, and damp grass is common. Many ramps are made from galvanized steel, aluminum, or coated metal, all offering different levels of protection. Galvanized and aluminum ramps resist rust best, while plain steel may require more maintenance. If your ramp will be exposed to the weather or you live in a damp climate, look for rust-resistant materials to ensure your ramp stays strong and safe over time.